What is Vertical Integration? And Is It Right for Your Business?

Vertical integration is like getting bangs.

Some people can really pull them off.

Some people can’t.

In this article, we’ll break down what vertical integration is, its benefits and disadvantages, its application in supply chain, and the factors to consider when deciding whether it’s the correct strategy for your company.

What is Vertical Integration?

Vertical integration is defined as the process through which one company gains control over two or more stages of production or distribution in its supply chain.

Let’s dive a little further.

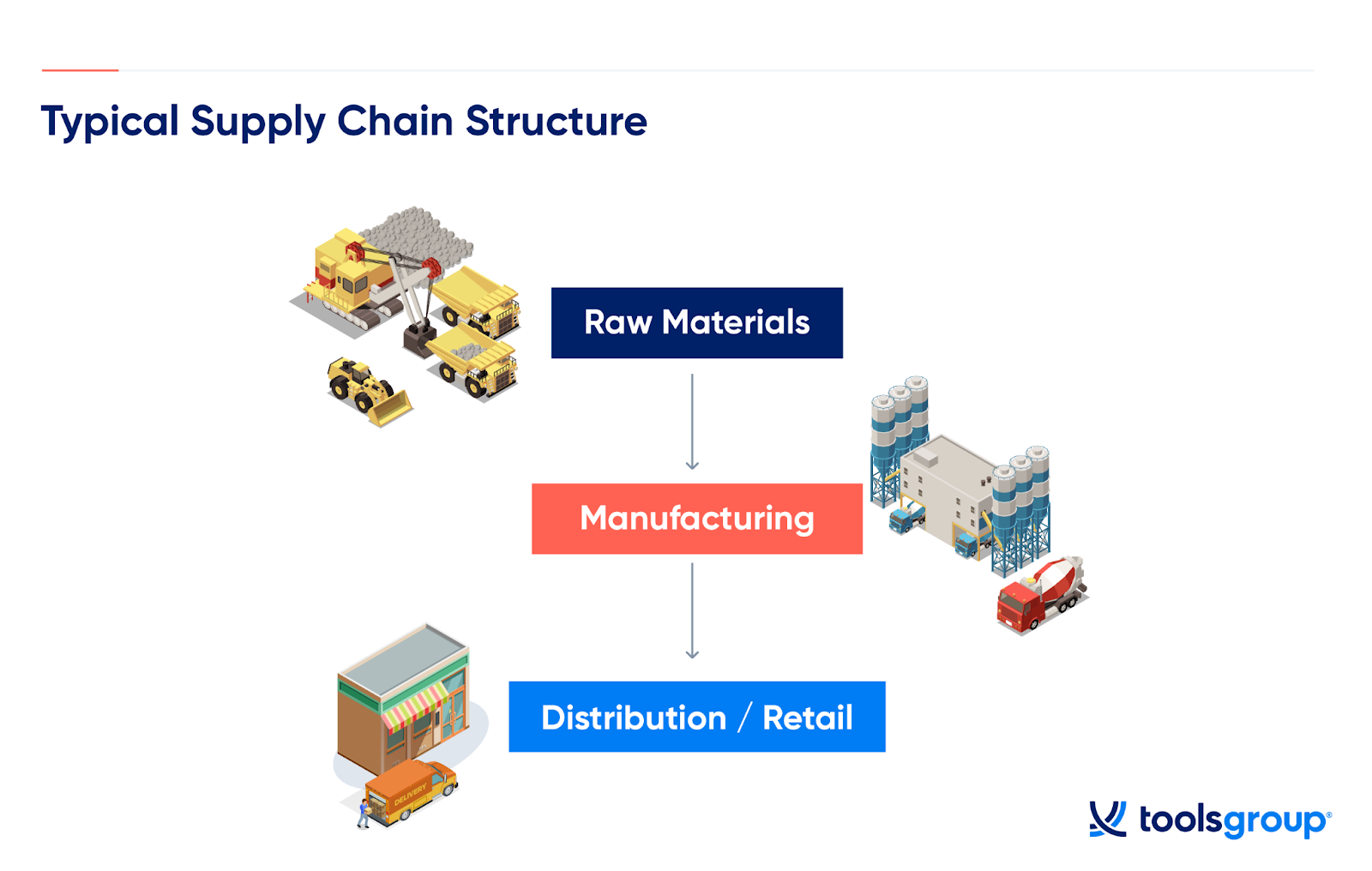

Here’s the usual flow of materials throughout the supply chain as it relates to vertical integration.

At the back of your supply chain, you’ve got your raw materials being procured.

In the middle, you’ve got your manufacturers that take those raw materials and turn them into finished goods.

And at the front of your supply chain, you’ve got your distribution and retail outlets that put the product into the hands of the end consumer.

Let’s assume for a moment that each of these stages is handled by a separate, independent company.

Each of these companies has its own end product or service that compliments the other stages but does not directly compete with them.

Vertical integration occurs when a company at one stage of the supply chain acquires, merges, partners, or establishes another company at a different stage of the supply chain, thereby controlling two or more stages in the production or distribution of a product.

Let’s use a hypothetical company to illustrate.

And since, as my sister puts it, I’m an “ice-cream-based lifeform,” we’re going to call this hypothetical company Scoops.

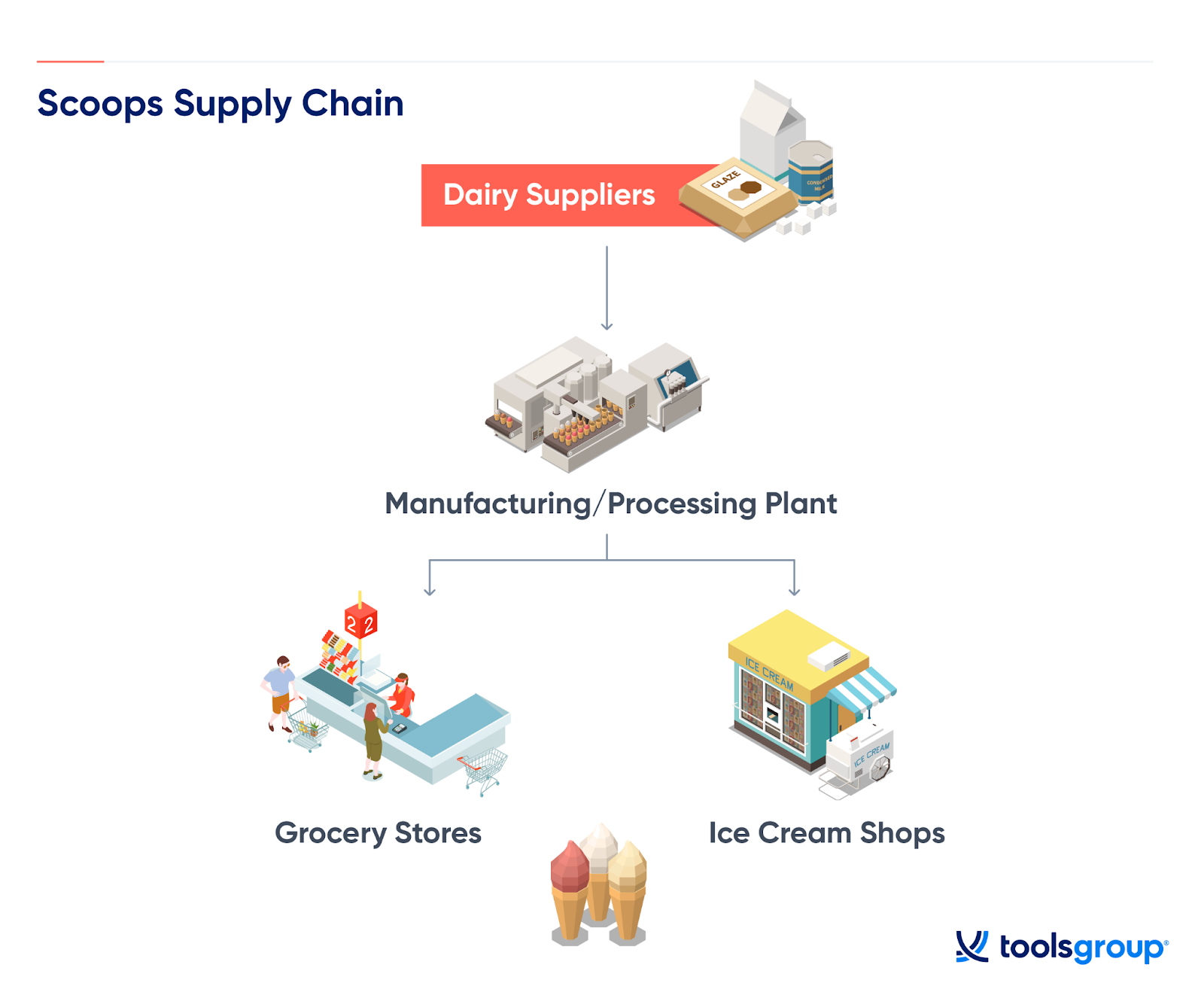

Scoops is a manufacturer that makes batch ice cream and pre-packaged ice cream bars and pints.

Scoops’ simplified supply chain looks like this.

Let’s say Scoops decides to acquire some of the ice cream shops selling its product.

In addition to owning and creating the product itself, Scoops now has a chain of branded retail shops.

By owning two levels of the supply chain, it’s vertically integrating.

Or let’s say Scoops decides to acquire its dairy supplier. Instead of an downstream acquisition, it’s acquiring operations upstream, but it’s still gaining control over two stages of the supply chain, so it’s still vertical integration.

What’s the Difference Between Vertical and Horizontal Integration?

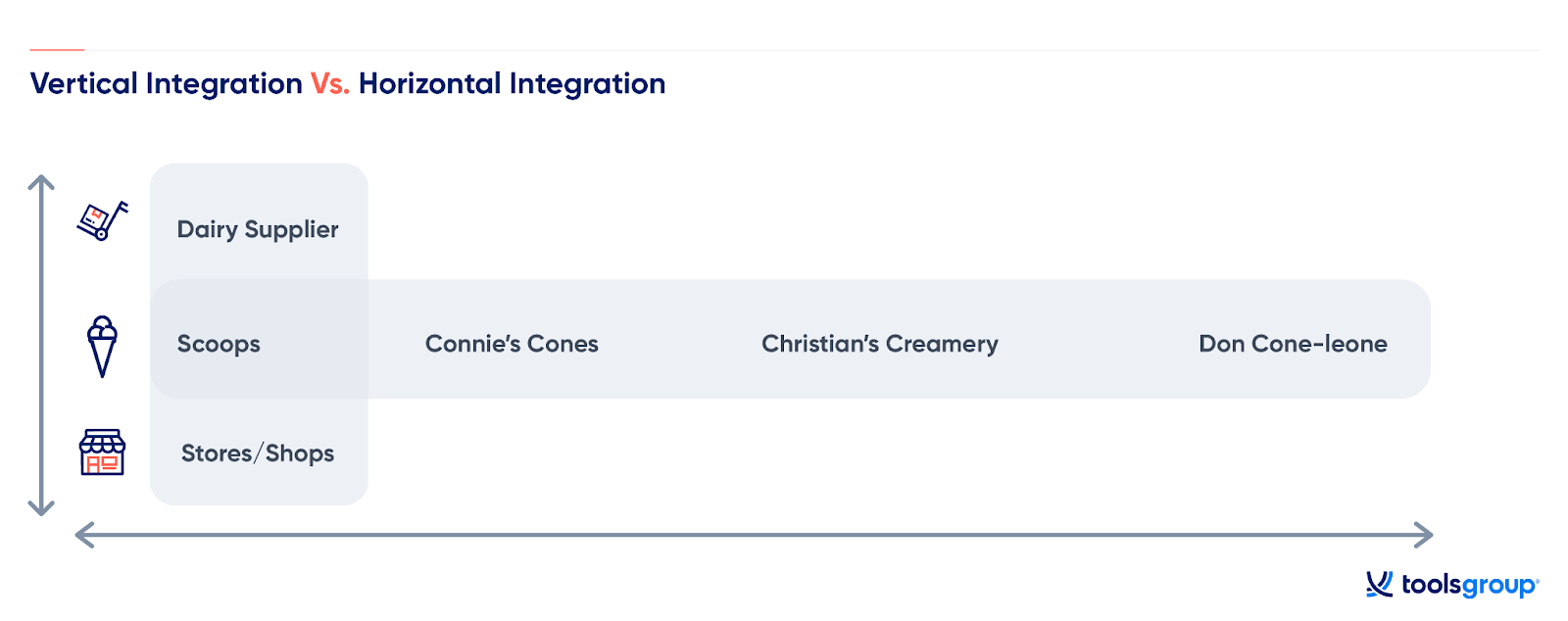

As defined above, vertical integration is when one company merges with another company at a separate stage of the supply chain.

So Scoops acquires its supplier or its retailer but not another manufacturer.

This is how vertical integration differs from horizontal integration.

Horizontal integration involves the acquisition of a competitor or a closely-related business that operates at the same or similar stages of the supply chain. Often, they produce similar products, provide similar services, or operate in similar industries.

So let’s say Scoops is considering horizontal integration.

There are other manufacturers that make up Scoops’ competition – Connie’s Cones, Christian’s Creamery, and Don Cone-leone Gelato.

To integrate horizontally, Scoops may acquire one or more of these other manufacturers.

It may do this to acquire proprietary flavors, incorporate dietary and organic products into its portfolio, expand into new markets, eliminate competition, or all of the above.

Types of Vertical Integration

Now that we have our definitions straight, let’s break down the three basic types of vertical integration. They are:

- Backward integration

- Forward integration

- Balanced integration

What is Backward Vertical Integration?

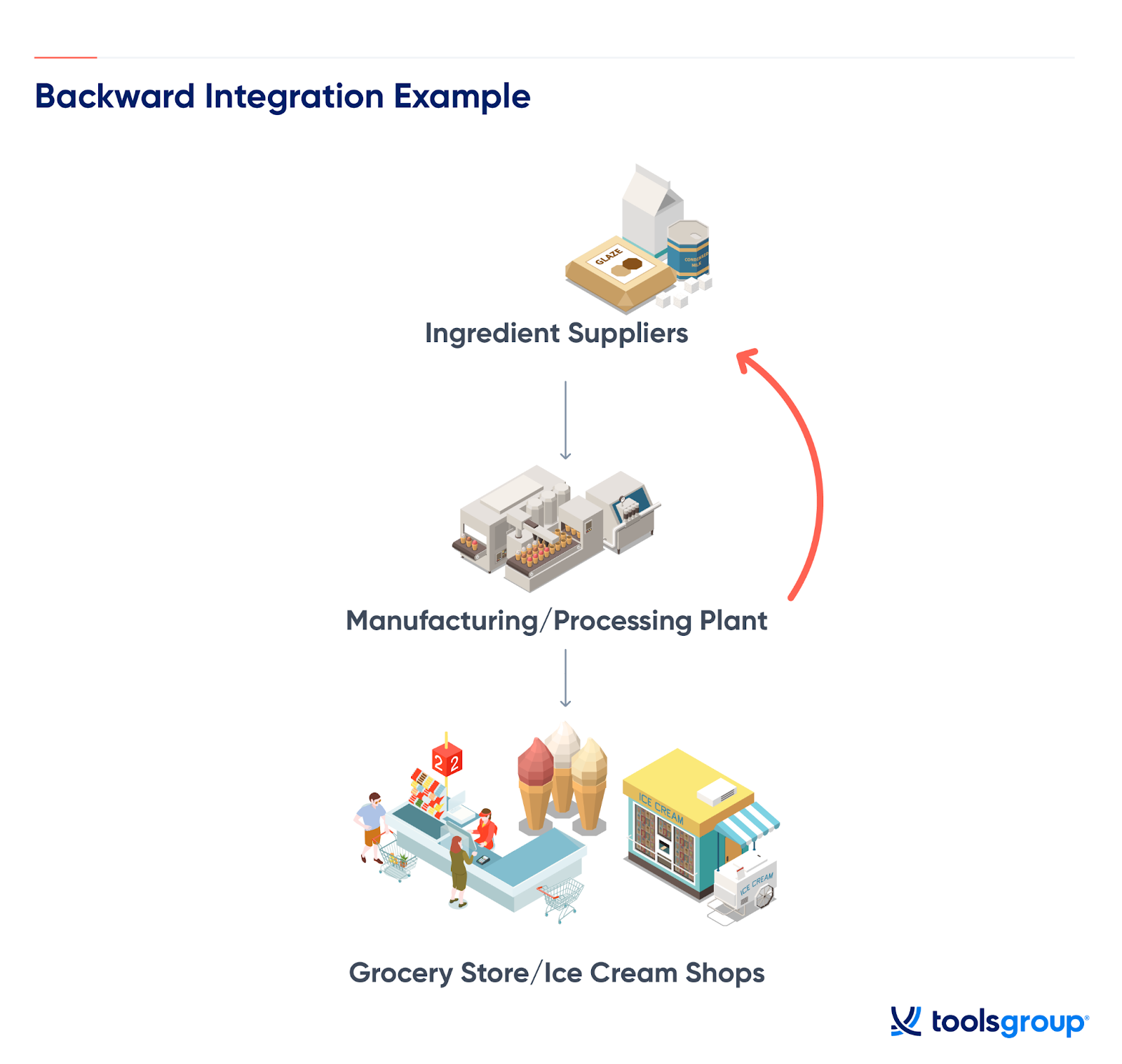

Backward integration occurs when one company takes control of the company or process behind it in the supply chain.

Essentially, the company buys its supplier.

In the case of Scoops, this means I could buy my dairy, waffle cone, chocolate syrup, brownie bits, cookie dough, or even peanut butter suppliers.

In this case, I would own both the raw materials and the production process.

What is Forward Vertical Integration?

Forward integration occurs when a company takes control of the company or process ahead of it in the supply chain.

Essentially, a company buys its customer.

So if Scoops sells its ice cream to ice cream shops and grocery stores, forward integration would entail Scoops buying those shops and stores, thereby owning both the manufacturing process and the retail operations.

It may also simply be that Scoops decides to continue selling to those grocery stores and shops but launches its own chain of Scoops ice cream parlors, thereby integrating forward into retail.

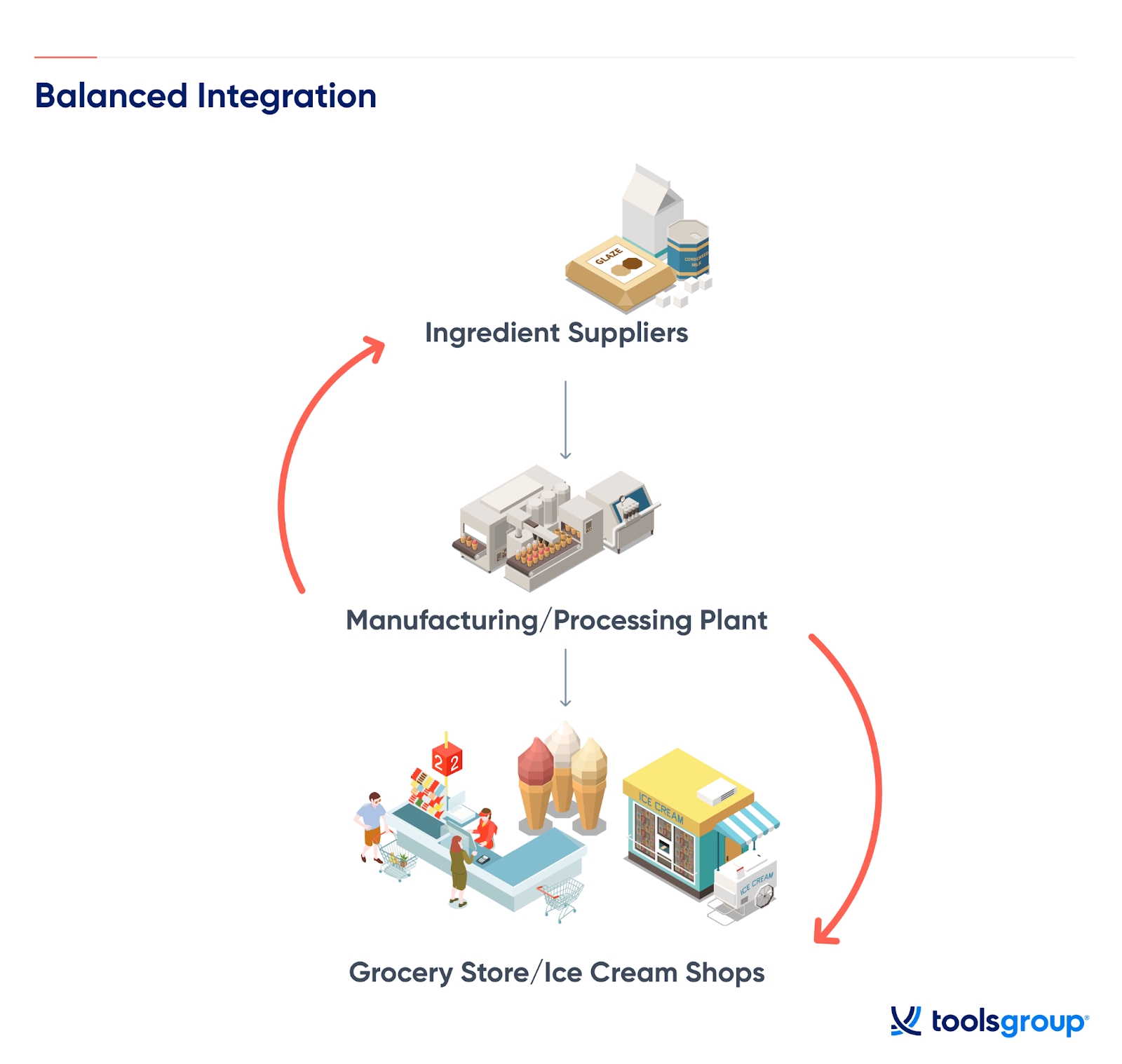

What is Balanced Vertical Integration?

Balanced integration occurs when a company buys both its suppliers and its customers.

Balanced integration is pretty rare due to the high costs required for multiple acquisitions. In addition, in some instances and industries, this sort of company behavior can lead to monopolies that violate antitrust laws.

The Advantages of Vertical Integration

So now that we know the “What” and the “How,” let’s talk about the “Why.”

Why do companies vertically integrate?

1. Supplier Stability

One of the perks of vertical integration is supplier stability.

With better communication and unified systems, a company integrated with its supplier can:

-

Monitor quality more closely

-

Increase turnaround times

-

Reduce transportation costs by placing factories in optimal locations, depending on raw material and consumer locations

Being able to count on your suppliers means customers can count on you.

2. Eliminating Hold-Ups

There’s sometimes a game of chicken going on between suppliers and buyers who are not integrated vertically.

Neither wants to relinquish a possible competitive advantage or bargaining power, but each is also aware that the other could just take its business elsewhere.

This contributes to something called the hold-up problem.

The hold-up problem stems from ambiguity in contracts between companies and their suppliers that can be exploited if the supplied products do not meet expectations or specifications.

Let’s say Company A agrees upon a price and quantity of items to be provided by the Supplier.

However, Company A claims that the items manufactured are not quite what they requested.

So Company A comes in with a lower price than originally agreed upon, holding up the Supplier.

But if the Supplier then gets a better offer from Company B, the Supplier can simply sell to Company B, and Company A is up a creek.

This stand-off can be eliminated with vertical integration since collaboration benefits both parties and there is no need to try to gain a competitive advantage.

3. Cost Reduction: Input Costs and Transfer Pricing

Combining two companies in a supply chain can greatly reduce the input costs, which are incurred to provide a product or service.

They include things like the cost of materials, labor, and transportation.

If a company is purchasing from suppliers on the open market, those suppliers want to make a profit.

So they add a little onto the price – a margin – usually dictated by quality, branding, and other market factors.

But with an integrated supplier, this margin is greatly reduced, lowering the overall cost of the item.

Plus, vertical integration can also help companies benefit from careful transfer pricing.

Transfer pricing is the price agreed upon by two divisions of the same parent company for exchanging goods or services.

Tax regulators don’t appreciate manipulating transfer pricing to avoid taxes, but there are legal ways companies can use it to boost revenue and allocate profits for different regions throughout the world.

4. Economies of Scale

The term economies of scale refers to how large businesses can reduce costs by producing more of a product.

This is due to an inverse relationship between cost and quantity, meaning the more you make, the lower your cost-per-item.

This can be due to:

-

Bulk pricing, which allows you to buy more raw materials at a lower price per unit, reducing your overall production cost

-

Managerial structures and organizational behavior that make production more efficient

-

Technological advances that allow you to be more productive and eliminate waste

A company needs to be large enough for economies of scale to work, so vertically integrating can give you the scale you need for these mechanisms to pay off.

5. Lower Consumer Prices

Because of the efficiencies of a well-executed and well-managed vertical integration, you can save a lot of money.

Passing those savings along to consumers and lowering your prices makes your brand more competitive and increases customer loyalty.

6. Expansion of Capabilities and Assets

Thoughtful acquisition can add value to your wheelhouse by incorporating specific skill sets and capabilities into the goods or services you offer.

Don’t make the best tires for your vehicles?

Acquire a good supplier and now you do!

These changes and improvements increase the quality of your products, which in turn allows you to fine-tune your marketing strategies to promote your value to the end consumer.

7. Expansion into New Markets

Integration can give you a foothold in regions where you may not have been known before or had a strong enough presence, allowing you to promote and sell your product to a whole new swathe of consumers.

More regions, more prospective customers, more chances to make money.

8. Better Overall Control and Visibility of Your Supply Chain

If executed well, vertical integration gives you much greater control over your supply chain.

Especially in these days of uncertainty, having visibility across your entire supply chain is a great boon.

Say you’re a fully integrated company, meaning you own the whole supply chain from raw materials to stores.

Since you own your retail operations, you have the ability to get more consumer behavior data – and get it faster. You can then provide that feedback to your suppliers and manufacturers so they can adjust production accordingly and quickly.

The Disadvantages of Vertical Integration

When it comes to vertical integration, it’s important to read the fine print and seriously consider the pros and cons.

If handled unwisely, vertical integration can be catastrophic to a business’s bottom line.

1. High Costs

Vertical integration is very much a “spend money to make money” situation, and there’s no guarantee that the resulting combined company will be successful and profitable.

You’re investing a significant amount of capital, not just to acquire a business, but also to buy or move factories or open up retail locations.

Sometimes, the risk is not worth it, and it’s more cost- and time-effective simply to outsource your raw materials and retail operations.

2. Time and Effort

Vertical integration requires many people from disparate industries and with varying degrees of experience to collaborate.

Synchronizing systems that were built independently of each other, and with different objectives, is no easy feat – particularly when employees are dealing with rapid change and uncertainties following an acquisition.

Putting these systems in the same sandbox and telling them to play nice needs to be handled carefully and doesn’t happen overnight.

It can take more time and effort to accomplish than companies have bargained for.

Tip: Communication through the change management process takes time, but it’s critical for retaining employees.

3. Management Difficulties and Loss of Specialization

When an acquired company is accustomed to autonomy, it can lead to hard feelings when those with expertise in a certain industry or field are suddenly getting orders from a new parent company who perhaps has less specialized knowledge.

These challenges can be compounded by the difficulty in finding a management team that can effectively handle both sides of the new business and quickly gain proficiency in an unfamiliar industry.

And while management is focusing on the integration strategy, they can get distracted and lose focus on the core competencies that made their original organization successful.

During integration, the complications stemming from change management and the lack of expertise at the management level can lead to unintended disruption to business operations, and, as a result, negatively impact the bottom line.

4. Satisficing Behavior

Here’s the thing about owning your supplier.

That supplier no longer has to compete with other companies in terms of price and quality to get your business.

This lack of competition can make a supplier a little…lackadaisical.

It’s like Senioritis. Your grades are high enough that even if they dip, you’re going to get your diploma, it’s summertime, and you’re just sort of coasting.

This is “satisficing.” Doing just enough to get by.

So sure, the material will be supplied or the product made.

But will it be supplied efficiently? With minimal waste? On time?

Will the quality be both consistent and up to standard?

These things can slip by the wayside without the drive of the open market to offer the highest quality at the best price.

5. Reduced Flexibility

Reduced flexibility is the flip side of supply and manufacturing stability.

If you only have one supplier, you may not have a fail-safe if that supplier can’t deliver when there’s sudden increased demand.

Retailers, especially in the world of fashion and apparel, and other FCPG companies are especially susceptible to challenges stemming from rapidly changing trends.

Let’s say, when planning your assortments, you expected light blue jeans to be all the rage this summer.

Then suddenly white jeans are taking off.

If you decide to cash in on the latest trend, you’re going to need a sizable and rapid influx of white denim for your factories.

But if your one supplier cannot provide that white denim, or cannot provide enough, or cannot provide it quickly, you won’t be able to meet demands and may miss out on serious seasonal profit.

There’s also the rigidity of the process.

A fixed manufacturing process may hinder the ability to adapt quickly to changes in the market.

Technology develops quickly, so you don’t want to be trapped in too rigid a process that can’t adapt.

If your supplier only makes one thing and only has one way to make it, you may fall behind on new processes, equipment, and advances that would make you more competitive and help you keep up with an accelerating and evolving marketplace.

6. Jeopardizing Other Business Relationships

Going back to our hypothetical company for a moment, let’s say Scoops has two dairy suppliers.

Scoops is looking to vertically integrate but decides it is better to acquire Supplier A than Supplier B.

The danger in acquiring only Supplier A is that Supplier B may feel snubbed and decide to no longer supply Scoops its product or to revoke some of the advantages and perks it provided as a valued business partner.

7. Dangers to the Free Market

Vertical integration can impede the free market by reducing competition too much and creating monopolies that no longer serve the consumers, as the company’s ability to set prices arbitrarily increases.

Vertical Integration in Supply Chain: To Integrate or Not To Integrate?

Vertical integration doesn’t have to be all or nothing. You’re allowed to cherry pick.

There may be some materials you can source and supply more efficiently yourself, and others that are worth outsourcing due to the cost, skills, or equipment they require.

So how do you decide?

There are five factors to consider when deciding whether or not to adopt this business model.

Let’s break this down into a little more detail.

Materials and Labor

The first two costs are pretty straightforward:

- The cost of the materials required to make a product

- The cost of employee wages and salaries

Ask yourself: how much do materials and labor cost now, and how might they change if you integrate vertically?

These costs are typically pretty steady, but keep in mind: Economies of scale could result in savings due to lower cost-per-item, but scaling can also require an increased headcount.

You may need more people in one department or factory, or you may need to set up offices or factories in new regions with varying laws on employment and benefits requirements.

Search Costs

Search costs are what you need to take into account if you’re not vertically integrating.

The term search costs refers to the cost of searching for a supplier on the open market.

Finding a quality supplier can take time, and time is money.

You want to have enough time to find a good company but not spend so much time that you’re losing money.

Plus, once you find that supplier, you have to negotiate a contract with them, maintain that contract, and begin litigation proceedings if need be.

This takes time and lawyers.

So when considering external suppliers, keep in mind that – yes, it’s in their interest to remain competitive by offering good quality and good prices – but that’s not the only financial consideration.

Administrative Costs

The next part of the equation is the administrative cost.

If you’re handling a certain stage of production or distribution in-house, what does that require?

Administrative costs include overhead costs like renting warehouses, maintaining machinery, and making sure the lights stay on.

It is also worth considering the cost of that “satisficing” behavior we talked about. (Is the work done, is it done well, is it done on time? Or is someone still out to lunch?)

If you aren’t monitoring your quality, you could end up with shoddy workmanship and low productivity.

You need systems in place to make sure your company is operating optimally, and this requires careful management and administration of resources.

Risk Assessment

The last part of the equation is risk assessment. What have you got, and what are you risking?

Potential losses to be aware of when assessing risk management can include capital, product quality, brand reputation, and relationships with employees, suppliers, and customers.

Here are a few questions to ask yourself.

- What is the possible payoff, worst-case scenario, and the probabilities of each?

- Is this an investment in a product or service with staying power?

- How much capital do you stand to gain or lose?

- Do you have the dream team with the skills to develop and execute an integration well?

- How will integrating affect employee sentiment regarding your company?

- If striking out on your own, perhaps there’s the risk of alienating a dependable retail outlet or supplier. Is it worth jeopardizing that relationship?

- Could an optimal customer experience – and loyalty – be put at risk?

These are just some questions to get you weighing the probabilities of success against possibilities of failure.

Vertical Integration in Retail

Retailers in particular stand to reap the rewards of vertical integration. This is because the speed of the vertically integrated supply chain can help retailers keep up with rapid fluctuations in the market and consumer expectations.

Having Data at Your Fingertips

POS data means retailers know what’s selling.

You can take that information and start making similar products with store brand labels and at store-brand prices.

Whether it’s Kirkland Signature at Costco, AmazonBasics, or Gold Emblem at CVS, retailers are cashing in on the sales data and trends at their fingertips to inform their own manufacturing and marketing strategies.

The right retail planning solution can help retailers process this data efficiently and accurately.

Social Responsibility and Supply Chain Visibility

If you are not vertically integrated, you may have suppliers located in a country where factories can easily exploit workers for long hours and low wages.

But not being integrated, you would be unaware of the exploitation.

By supporting these businesses, you could end up enabling inhumane working conditions and facing legal consequences, consumer backlash, and a scramble to replace or sanction your supplier.

If, however, you’re vertically integrated with your supplier, you have visibility into and control over how that company functions and treats its employees.

And considering supply chain transparency requirements are increasing due to both government regulation and customer expectations, you want to make sure you have that supplier visibility.

For instance, in a recent proposal from the European Commision, large companies in the EU would be required to “check that their suppliers from around the world do not use slave or child labour and that they respect environmental standards.”

Consumer expectations are transforming as well.

Both Gen Z and Millenials “are the most likely to make purchase decisions based on values and principles (personal, social, and environmental)” with nine out of 10 Gen Z consumers believing companies have a responsibility to address environmental and social issues.

Vertical integration can help you keep up regulations coming down the line and increasingly ethically-conscious consumers.

Necessity of Supply Chain Planning Software in Vertical Integration

Let’s say you’ve done your due diligence; you’ve assessed the risks and you’ve developed a vertical integration strategy.

Now it’s time to integrate your technology.

Remember: The entire goal of vertical integration is to drive business growth. Implementing supply chain planning software to increase efficiency, minimize losses, and maximize product margins is one of the best ways to drive that growth – and ensure a competitive advantage.

The more you can automate, the better.

In fact, with labor shortages spiking, companies across the board are turning to automation, with 53% planning to increase automation in 2022 to focus staff on high value added activities.

Automation can help eliminate the drudgery of manual planning and spreadsheets and help your planners make smart inventory and replenishment decisions.

And since the acquisition process already involves assessing and integrating technology systems, vertical integration provides the perfect opportunity to implement retail planning software that ensures alignment and more accurate demand forecasting across your supply chain.

Final Takeaways on Vertical Integration

There’s no perfect answer for how to design your supply chain.

So when you’re wondering what to bring in-house and what to outsource, ask yourself:

-

What are the costs of materials and labor?

-

What are your search costs as opposed to keeping production in house?

-

How risky is each decision, and are the benefits worth the possible disadvantages?

-

How comfortable are you with that level of risk?

Vertical integration can be a powerful tool, but it comes with its challenges, and it’s best to go into it with eyes wide open.

Companies who have vertically integrated are discovering increased growth and unlocking maximum profits thanks to supply chain planning software, which can reduce forecast errors by 10-20%.

Find out more supply chain planning software – and how to choose the right solution for your business – in the supply chain planning investment guide.