Supply Chain Communication: 4 Effective Strategies for Better Supplier Communication

Effective communication is one of the keys to running a successful supply chain, yet it is often overlooked in importance until it becomes an issue.

With evolving customer behaviors and buying patterns, increased competition, and a globally disrupted supply chain, the need for effective communication between businesses and their suppliers has never been more apparent.

Back to Basics: Laying the Groundwork for Successful Communication with Suppliers

Good communications skills are universally lauded as one of the keys to success in almost any field.

Raise your hand if you’ve seen “good communications skills” on a job description or heard “let’s keep the lines of communication open.”

But has this line lost meaning like other tired clichés?

Let’s hope not, because your ability to effectively communicate with your suppliers has a direct impact on customer service levels, your bottom line and brand reputation.

Failure to communicate can result in missed deadlines, untimely deliveries, increased transportation costs, shortages, and irate customers.

And, good supplier communication is one of the most effective ways to manage continued supply chain shortages.

The Characteristics of Supply Chain Communication

So how do we define communication? Here are a few basic definitions and characteristics to keep in mind:

- Exchange of ideas

- Flow of information

- Connection

- Collaboration

- Persuasion

- Inspiration

Simply put, communication is the engine that powers organizations.

But what happens when there’s a breakdown?

Imagine you’re a high-end boat manufacturer in North America preparing for the warm weather.

Your demand planning and forecasting strategy are in tip top shape. All internal stakeholders are ready to execute their part.

But one crucial supplier needed a much longer lead time than usual.

Now the domino effect begins and one of the biggest casualties is your service level, not to mention with a high ticket item such as a boat, your revenue numbers could be severely impacted.

So how do you improve supplier communication for a more streamlined supply chain?

Here are four tips for better communication with suppliers to overcome today’s supply chain challenges and help you ensure supply chain planning success.

1. Set Clear Expectations from the Beginning When Communicating with Suppliers

Establish a clear communication path at the beginning of every new relationship.

What data do you need from suppliers?

What do they need from you and what communications channels or tools have been established?

Ensure that whatever supply chain planning technology you choose easily enables back and forth communication, allows for status updates and allows access to part numbers/identifiers.

Amid today’s supply uncertainty, it’s even more crucial to be transparent with your suppliers about production forecasts to enable them to give advance notice to manufacturers of what they can deliver and when.

Visibility to supply requirements over a longer horizon sharpens your upstream plan and allows you to plan further in advance.

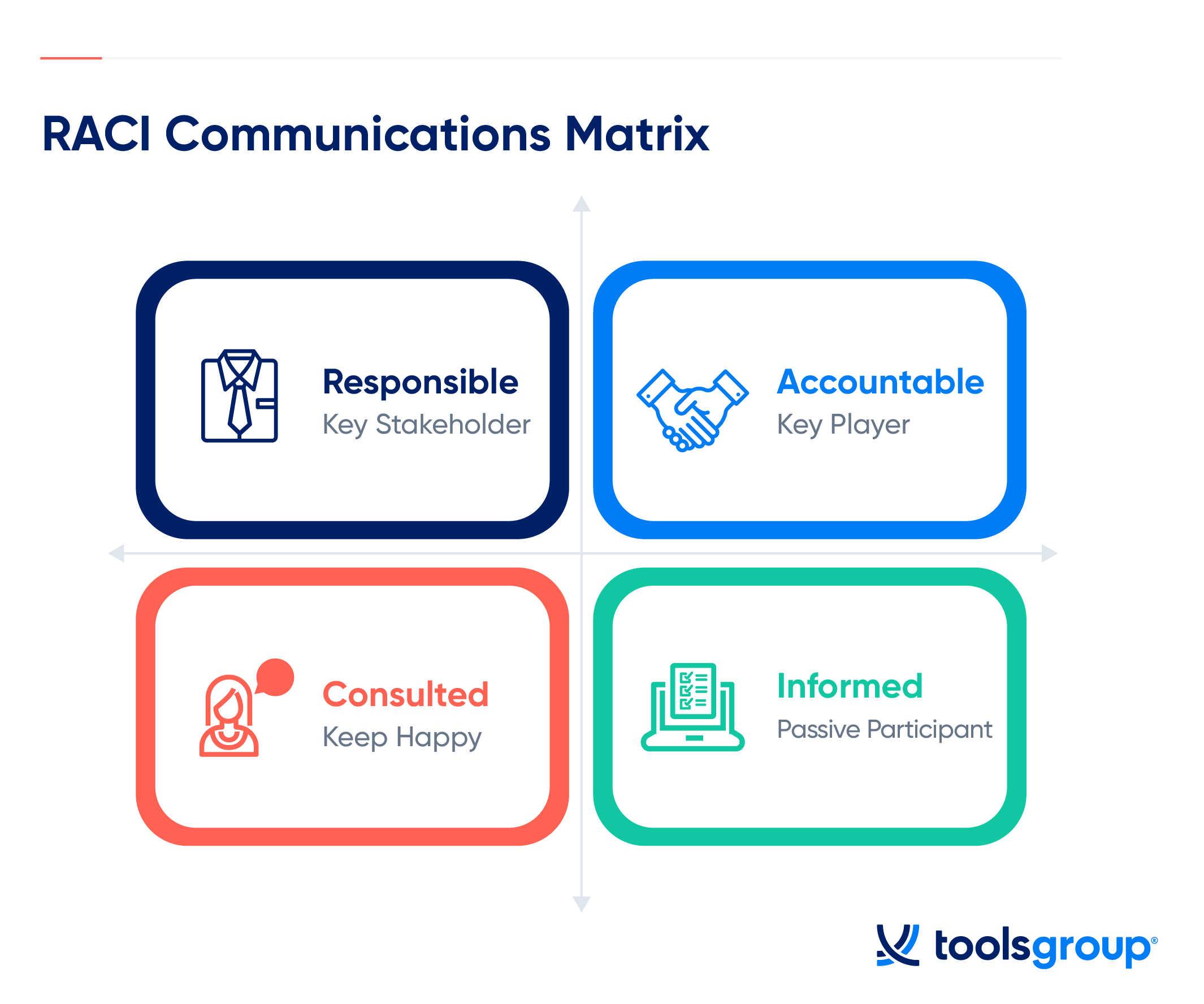

2. Identify Supply Chain Planning Stakeholders

Determine who’s leading the charge with your supplier relationship and related stakeholders.

A RACI matrix might be a quick way to establish what role each stakeholder plays in the supplier relationship and their level of importance or responsibility within the chain of communication.

According to Harvard Business Review, good leadership is about communicating “Why?”

Once you’ve created a plan, successfully set up your processes and determined the players, take it a step further by communicating the why.

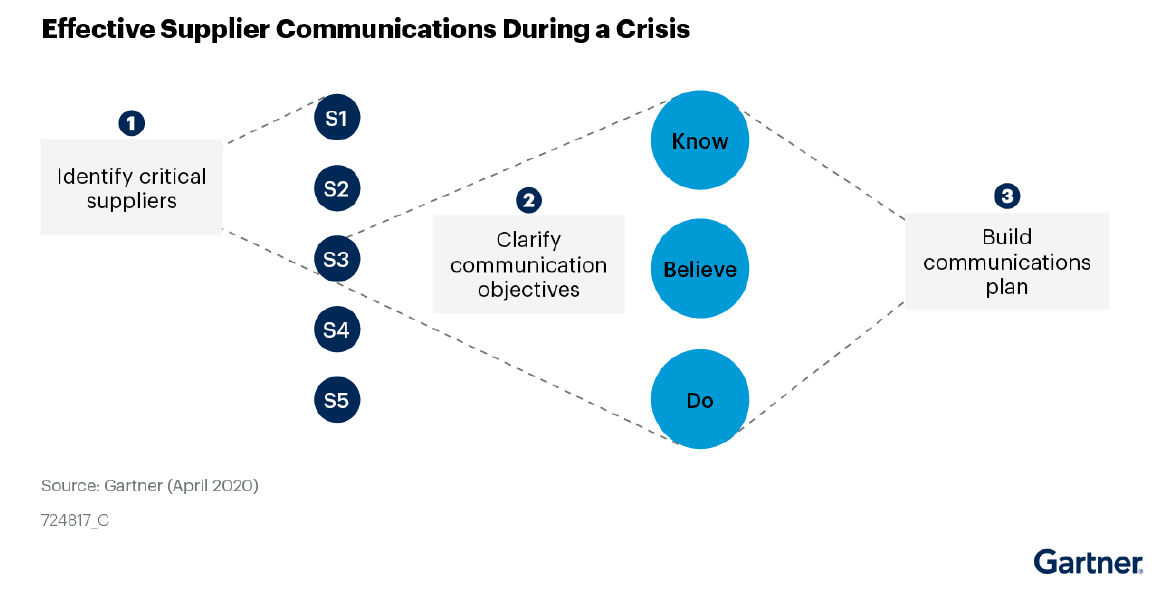

3. Prioritize your Suppliers and Relationships When Communicating With Vendors

Nurture your supplier relationships at all times.

Now, all suppliers may not be created equal; some may be of more strategic importance to your business than others, but they all have an impact on the business.

Gartner has this advice: “Segment your supplier audience based on their criticality to the business. This will help determine the message and communication channels to use.” ¹

-

Suppliers with high impact on revenue

-

Single-source suppliers

-

Sole-source suppliers

-

Suppliers in most affected regions

-

Suppliers shipping to manufacturing locations in highly affected regions

-

Suppliers of essential raw materials or components

Be proactive in nurturing those relationships, don’t wait until there’s a problem.

Regular meetings with your suppliers are a great way to alleviate their concerns, address any issues and solidify your relationship.

4. Be Proactive and Transparent in Supplier Communications to Meet Business Goals

Being transparent with your suppliers about production forecasts enables them to give advance notice about what they can deliver and when.

Better yet, you and your suppliers can collaboratively determine changes or cuts needed in your short-term plan.

Take it a step further by discussing how far out you need to plan and understand their capacities.

Based on those discussions, you can make decisions on whether to shift capacities to other factories temporarily or assess what you can produce quickly and efficiently.

There’s no guarantee that the supply you normally order will be available, so it pays to be smart about what you order to maximize service and profitability.

Analyze which supply orders will contribute to higher margin sales, which are most likely to sell, or what’s needed to fulfill backorders quickly.

You’re essentially “prioritizing” the type of demand to fulfill for your suppliers so they can make better decisions on production requirements.

This is an especially valuable practice when supply chainvolatility and disruption are prevalent.

Effective communication won’t happen overnight.

It can take months or even years to develop but just remember that having a communication plan is not the be all to end all.

It’s the beginning of a living, breathing and evolving process.

If your supply chain was facing a crisis, you wouldn’t implement a plan of action designed for more normal times. Your strategy would evolve.

When in doubt, keep these key questions top of mind to help drive successful planning and maintain thriving relationships with one of your most valuable assets—your suppliers.

What is your goal?

Who is your audience?

What is your message?

How should you deliver your message?

What is your feedback mechanism?

Better Communication with Suppliers Is Essential to Supply Chain Planning Success

Keep communication proactive, especially if your supply chain is complex.

When internal stakeholders are aligned with suppliers, it makes for a more creative and collaborative process that can help minimize supply chain risk.

The dangers and fallout from poor communication cannot be overstated because it often translates into lost revenue and fractured relationships, and the customer ends up losing.

Or perhaps not. Customers wield more power than ever before and if you can’t deliver the goods, they’ll find a competitor who can.

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and is used herein with permission. All rights reserved.

This graphic was published by Gartner, Inc. as part of a larger research document and should be evaluated in the context of the entire document.

¹ Effective Supplier Communications During the COVID-19 Crisis. Miguel Cossio, Caroline Chumakov. Refreshed 14 October 2021.