Managing the Long Tail of the Supply Chain: Part 1

This month we will dedicate four posts to an important but not well understood supply chain planning phenomenon called “long tail” demand. Consumer Goods Technology (CGT) recently hosted an excellent web seminar on this topic entitled “Driving Results Despite Item Complexity”. We’ll focus on each presenter’s message, each with their own perspective.

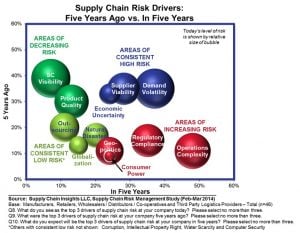

First up: Lora Cecere, founder of Supply Chain Insights. Her survey results show that demand volatility is the area of the largest pain and an area of consistent high risk for most companies.

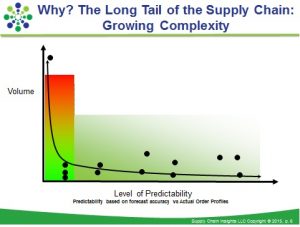

Item proliferation, shortened product life spans and omni-channel sales have caused companies to struggle with increased demand volatility and long tail demand – items that aren’t so predictable and don’t have high volumes, but are still important to the business.

The problem is that supply chains designed in the 1990s haven’t kept up with this fundamental change in the business. They were designed for high product volumes and predictable demand. They have been managed by deterministic optimization and rules-based consumption techniques.

“In most businesses, the tail of the supply chain has grown and the design of the systems and the design of the supply chain have not kept up with the growth of the long tail of item complexity,” Lora says.

“Most companies today don’t understand that the ability to forecast products is worse than it was 5 or 10 years ago. Because we have elongated the number of items on the item master and increased business complexity, our ability to use traditional forecasting tools and break that forecast into replenishment cycles is not as effective as it was.”

She says that most companies design their supply chain to be efficient, but they don’t design it to be agile—to handle volatility while still providing the same level of cost, quality, and customer service. Companies want more agility and speed and to be more proactive, but most are still supply-centric. “They don’t understand the concept of long tail or demand latency, and they really haven’t looked at the translation of channel data.”

“All people know is that they’ve got pain. They know their supply chains are not responsive, but they keep going back to their supply-centric view, as in ‘Let’s just redefine transportation and logistics.’ They’re not embracing the demand cycle, to align the demand cycles to the supply cycles.”

Lora says that companies need to get to a demand-driven network, but she says that the worst place to start is to say “I’m going to work harder at forecasting”. Demand forecasting is getting progressively harder. And with traditional systems, as you move down the supply chain, the bullwhip effect exacerbates the problem by distorting and amplifying the demand signal in the long tail. The added latency inherent in slow moving items causes more bullwhip, making it harder for planning systems to handle.

So she encourages businesses to look more closely at their long tail and how it’s changed and grown over time. Cecere says that “on the long tail you need to apply multi-tier inventory optimization techniques, you need to look at demand sensing, and you really need to look at channel data usage.” In short, the key is to focus outside-in— and become more demand and market-driven.

This is part 1 of a series of 4 blog posts on the Managing the Long Tail of the Supply Chain topic. Below are all four blog posts:

- Part 1 – Managing the Long Tail of the Supply Chain

- Part 2 – Pareto is Dead

- Part 3 – How Dart Achieved a 99.6% Service Level

- Part 4 – Five Takeaways