Multi-echelon Inventory Optimization (MEIO) vs Inventory Optimization

The subway system is the lifeblood of New York City, pre-COVID carrying an average of 5.5 million people per day in 6,684 cars across 472 stations.

Each station is part of a larger system and operates on a set schedule under one management umbrella.

Imagine what would happen if each station optimized its schedule and traffic independently: city-wide chaos would ensue.

Now consider that by not optimizing your inventory from a global vantage point you may be creating, if not outright chaos, a much less efficient network than you could have.

A complex system like this can benefit from employing the right approach to inventory management.

Manufacturing Supply Chain Challenges

First, let’s consider the inherent challenges of the modern manufacturing supply chain.

Getting Inventory Where It Will Best Serve the Customer

When it comes to inventory management, each piece must operate as a part of a global integrated system to be most effective.

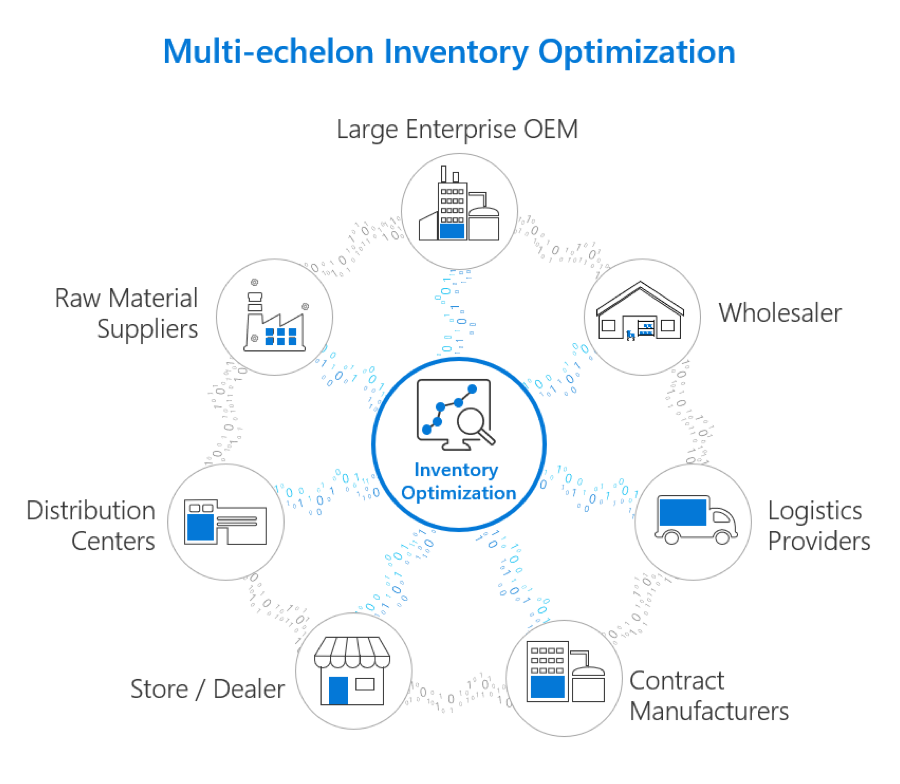

All manufacturing echelons–raw materials suppliers, factories, distribution centers, and wholesalers–need to ensure that the right stock is in the right place at the right time to truly serve the end customer.

This is no easy task.

Outdated Planning Solutions and Methods

Making matters worse, many manufacturers are currently using legacy systems with rules of thumb, outdated algorithms, or personal instinct to manage inventory.

For example, an organization may set inventory targets for a specific SKU-Location based on average demand for a broad product family across a wide geographic region.

This approach does not account for variability; individual products may have a similar average demand but dramatically different incoming order patterns.

Two Ways Manufacturers Are Overcoming Supply Chain Challenges

To stay competitive, manufacturers are turning to two types of solutions to handle their supply chain: inventory optimization (IO) software and multi-echelon inventory optimization software (MEIO).

The overarching goal of both IO and MEIO solutions is to efficiently set inventory levels to accommodate forecasted demand. This enables manufacturers to keep inventory levels low, move inventory as quickly as possible, and ensure high service levels for customers.

Let’s first look at how inventory optimization (IO) solutions tackle effective supply chain planning, then compare it with MEIO.

The Basic Approach to Inventory Optimization

A good inventory optimization solution identifies optimal inventory levels at individual stages in the supply chain. Manufacturers can accurately address demand volatility and manage even slow-moving and intermittent demand products with advanced analytics, statistical algorithms, and machine learning.

Inventory optimization will model demand and determine the appropriate inventory for individual echelons in the supply chain.

As an example, if a supply chain contains raw material suppliers, factories, and warehouses, most inventory optimization solutions manage stock at each stage separately—optimizing supply at warehouses distinct from factories.

Manufacturers realize significant improvements when they leverage statistical demand forecasting, advanced analytics and intelligent inventory adjustments instead of the old rules of thumb, arbitrary segmentation, and one-size-fits-all approaches.

The benefits of supply chain planning software are powerful and usually rapid: improved service levels, increased working capital, and decreased operational costs.

The Multi-Echelon Inventory Optimization Approach

Complex supply chains benefit from MEIO solutions, which take inventory optimization a step further.

An effective MEIO solution suggests the right levels of inventory at each stage of the supply chain by simultaneously optimizing inventory balance across multiple echelons and locations.

Picking up from our previous example, with an MEIO approach, manufacturers would analyze demand forecasts across an all-encompassing view of the supply chain.

So how does this approach improve inventory planning?

MEIO enables manufacturers to strategically stock individual inventories across all echelons of the supply chain–increasing customer service levels while simultaneously decreasing costs.

For instance, the MEIO software might suggest the right “decoupling points” and adequate levels of materials, components, subassemblies and finished goods in any location of the entire supply chain.

It can optimize the balance of inventory across different locations for optimal “staging” and different Bill-of-Material (BOM) levels for optimal “postponement”.

It also enables manufacturers to achieve the optimal replenishment frequency for individual products at each location.

The increased visibility that MEIO provides empowers centralized demand planning, reduces cost across the supply chain and streamlines operations.

Inventory optimization (IO) is a great first step to improving overall supply chain performance, but for companies with complex supply chains, MEIO goes further towards optimizing service levels while minimizing inventory costs.

Looking for a Real World Example?

The company's homegrown planning solution couldn't keep up with its tremendous growth.

With the help of an automated solution, Franke gained control of its multi-echelon environment worldwide, reducing seasonal inventory peaks while improving forecast stablity and increasing productivity.

Five More Inventory Optimization Segments

Here are five more inventory optimization distinctions that you should be aware of if you are considering an inventory optimization solution. Knowing which types are important to your business is an important step to determining which solution best fits your needs.

1. Inventory Configuration

Inventory Configuration addresses the issue of, “In what form should I hold my inventory? As raw material, finished goods, or something in between?”

You achieve an optimized inventory configuration with a postponement strategy, which optimizes the trade-off between upstream and downstream inventory to identify the most globally efficient balance. Positioning inventory downstream, nearer demand, is traded off against positioning inventory upstream, where it has the broadest range of possible uses.

In manufacturing operations, adequate levels of assemblies and finished goods are positioned to deliver the final product as late as possible within an acceptable service-time.

Partially processed Bill-of-Material (BOM) inventory is positioned to gain higher commonality of raw material and components.

This risk pooling approach frequently requires less inventory. For example, postponing final labeling, packaging or kitting reduces inventory requirements because the same inventory can satisfy multiple types of demand.

2. Stage Optimization

Stage Optimization applies the same postponement principles, but to the distribution network, where the form of the inventory usually does not change, only its place in the network.

It addresses decisions about whether to stock inventory at the factory, in a centralized distribution center, at a regional network, or some combination of the three.

Downstream inventory is closer to customer demand, but upstream inventory allows for risk pooling across many regions, customers or channels (such as retail stores, eCommerce, etc.).

3. Mix Optimization

Mix Optimization (also called Service Optimization or Service Level Optimization) allows you to position the inventory across the distribution network to meet high customer service level objectives in a much more efficient manner than simply creating a homogeneous mix of one-size-fits-all inventory.

Instead, mix optimization creates a blend of different service level targets for each individual SKU in each location to achieve an aggregated service level target that meets the business objectives.

For instance, instead of assigning all SKUs in a class a 98% service level, a global 98% service level target is achieved by optimally setting individual SKUs’ service levels at 95%, 97%, 99.5%, etc.

This optimal service level setting achieves the same overall objective with far less inventory expense.

4. Lot Size Optimization

Lot Size Optimization is the simultaneous optimization of safety stock and cycle stock values.

Optimal lot sizes are a function of the targeted service level, safety stock, manufacturing set-up cost or the replenishment handling cost versus the inventory holding cost and other factors.

As the lot sizes increase, set-up or handling costs decrease while the stock holding costs increase in line with average stock level (but not linearly, as is used in most classic models).

5. Prebuild Optimization

Prebuild Optimization (also called Build Ahead Optimization) is used in two cases.

- The first case is a finite supply capacity environment with strong seasonal demand or reduced supply due to shut-down or maintenance.The prebuilt inventory should be carefully planned to cover the excess demand in the period of inadequate supply.Inventory optimization dynamically defines the prebuilt inventory requirements on the basis of the updated time-phased forecasts and supply capacity until the end of the season.The inventory mix covers the excess demand during the season without losing sales or accumulating overstocks of the wrong inventories.Prebuild analysis may be an important component of Sales and Operations Planning (S&OP).

- The second case occurs towards the end of a product life when you define an end of production date.

Service parts for such products should be prebuilt to guarantee service for a period defined by an SLA, company policy or by law.Similar to the first scenario, based on the residual supply capacity and the evolving forecast for such parts in the period, prebuilt inventory requirements should be dynamically calculated to minimize obsolescence or resupply after the end of production.

Final Takeaways on Inventory Optimization and MEIO

No supply chain operates in a vaccuum. There is the constant push and pull of global forces, like supply shortages, geopolitcal factors, and even weather disruptions.

Proper inventory optimization can help you understand the needs of of your supply chain on a more granular level and make wise choices about where, when, and how you handle your stock.

This is why it’s imperative to have the right tools in place to give you that control before those global forces pull your supply chain off balance.

When’s the last time you did a temperature check on your current planning process? Do you know what to look for?

Discover the warning signs of an outdated system and what you can do to remedy them.