Advanced Demand Forecasting: A Complete Guide

Demand planning has evolved dramatically in recent years. Businesses have to shift from supply-focused approaches to advanced demand forecasting models. Traditional forecasting methods often fail under high variability, leading to excess costs, stockouts, and obsolescence, and still struggle to balance accuracy with agility.

What is Demand Forecasting in Supply Chain Management?

When planning your demand forecast, it’s essential to master the fundamentals. This process requires a diverse skill set to navigate its numerous complexities and ensure success.

Demand forecasting in supply chain management is the process of predicting customer demand, supply trends, and pricing fluctuations. It leverages historical data, competitive intelligence, and external factors to guide inventory planning and resource allocation. Given today’s volatile market conditions, companies must adopt more advanced forecasting techniques to improve resilience and customer service.

Top Four Strategies for Demand Forecasting Success

In the current landscape, the challenges of supply chain disruptions remain a pressing concern. Whether you’re in manufacturing, retail, or another industry, navigating uncertainties can feel like solving an intricate puzzle. To help you stay ahead, here are four strategies that supply chain leaders are using to win at demand forecasting.

1. Plan for Uncertainty with Probabilistic Forecasting

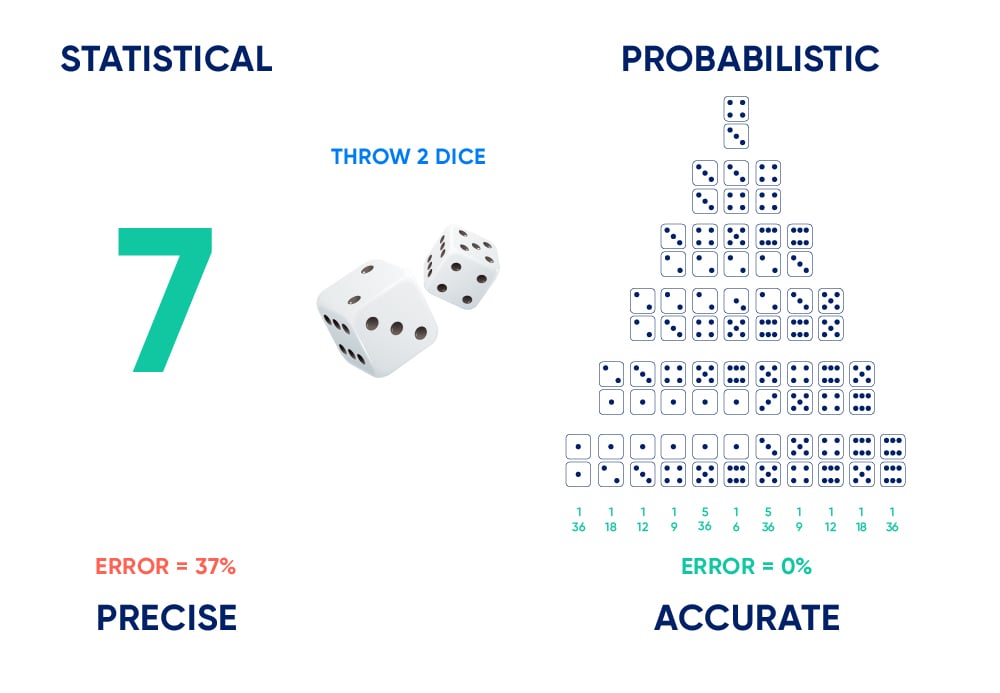

Traditional forecasting aims for a single-point estimate, but real-world demand is unpredictable. Probabilistic forecasting accounts for uncertainty by modeling demand variations. This approach enhances risk management, improves service levels, and strengthens resilience against disruptions.

The key advantages of probabilistic forecasting include:

- Comprehensive risk assessment across multiple scenarios

- Dynamic safety stock calculations based on service level targets

- Better handling of seasonal variations and market fluctuations

- Improved new product introduction forecasting

- Enhanced promotion planning capabilities

Real-world applications show that companies implementing probabilistic forecasting typically achieve 15-25% higher forecast accuracy compared to traditional methods, especially during periods of market volatility.

The image compares a statistical forecast to throwing 2 dice (left) and its probabilistic forecasting equivalent (right).

2. Leverage ML-Powered Demand Forecasting

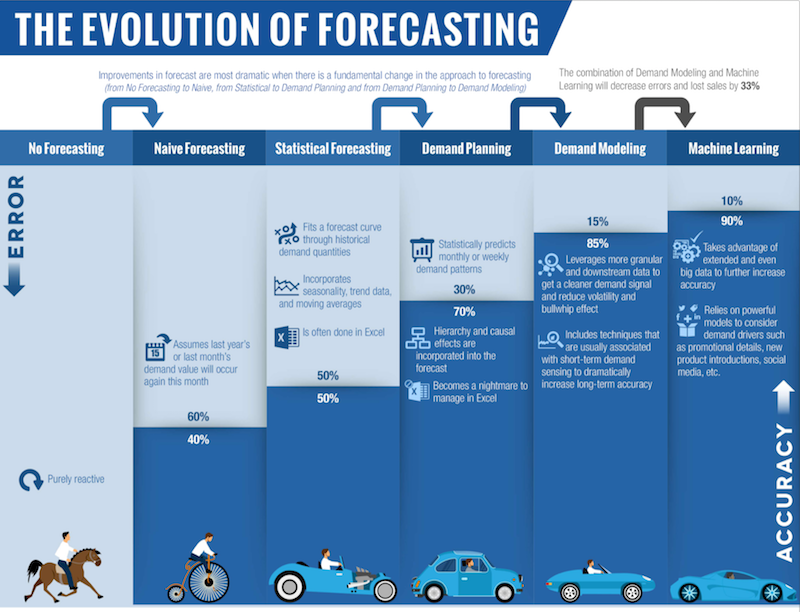

Machine learning (ML) is transforming advanced demand forecasting by analyzing vast datasets, detecting hidden patterns, and continuously refining predictions. Machine learning-driven forecasting reduces error rates and enhances adaptability to factors like seasonality, new product launches, and external events (e.g., weather, social media trends).

In today’s fast-paced world, businesses are turning to machine learning for demand forecasting more than any other area in supply chain planning. As you strive to elevate your supply chain forecasting, understanding your current forecasting maturity stage and the steps needed to progress is essential. Incorporating machine learning into your demand planning can decrease forecast error and lost sales by over 30%.

Advanced ML algorithms can now process hundreds of variables simultaneously, including:

- Historical sales patterns

- Economic indicators

- Social media sentiment

- Weather forecasts

- Competitive actions

- Local market events

- Price elasticity

- Promotion effectiveness

These capabilities enable organizations to create highly accurate, granular forecasts at the SKU-location level, something previously impossible with traditional methods.

3. Automate Forecasting to Enhance Supply Chain Agility

As supply chains grow more complex, the role of the supply chain planner has never been more critical. By automating routine planning tasks, organizations can empower their planners to focus on high-value strategic decisions, driving better business outcomes and greater resilience.

AI-driven supply chain automation excels at handling large-scale data analysis, identifying patterns like seasonality and shifting consumer behavior with speed and accuracy beyond human capability. This not only enhances forecasting but also amplifies the expertise of retailers and merchandisers who understand their customers best.

Take Shamir Optical, for example: by automating planning decisions, they scaled operations across 20 locations each with 35,000 SKUs—without adding to their team of just three planners. The right technology doesn’t replace planners; it enables them to achieve more than ever before.

Modern automation platforms offer several key capabilities:

Advanced Exception Management:

- Automatic identification of forecast anomalies

- Smart alerting for unusual demand patterns

- Proactive risk identification

- Automated adjustment recommendations

Intelligent Workflow Optimization:

- Priority-based task allocation

- Real-time collaboration tools

- Automated approval processes

- Performance tracking and analytics

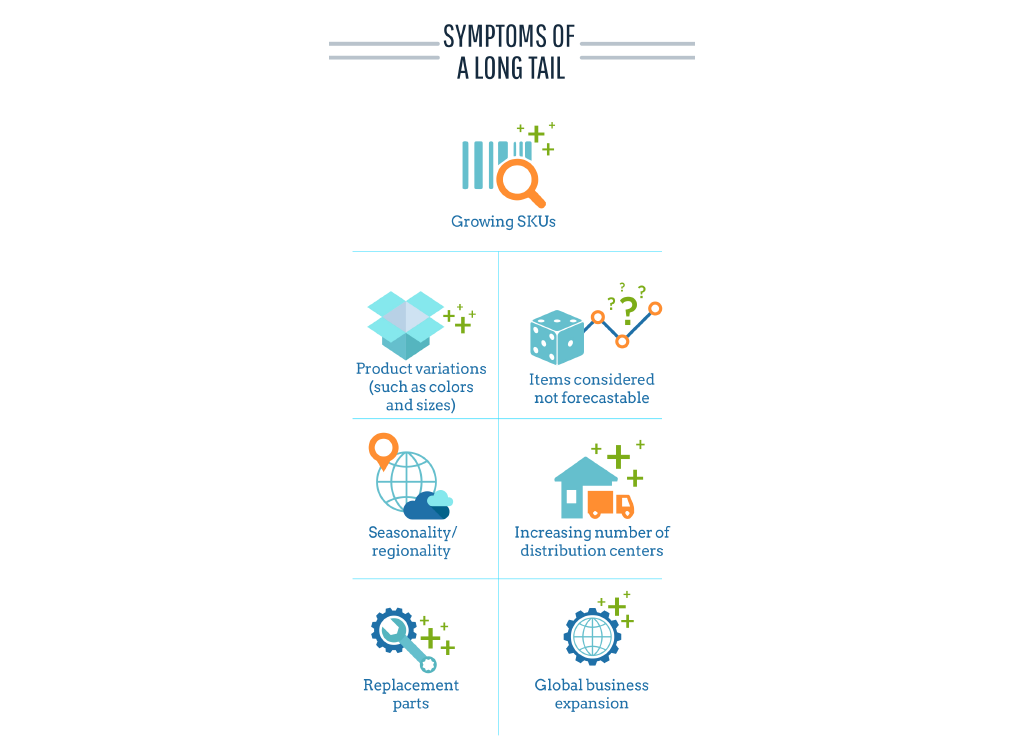

4. Master supply chain forecasting for intermittent demand

As consumers demand an increasing variety of product options, it results in more intermittent demand and slow-moving inventory. The key to forecasting intermittent demand is to accurately and reliably model demand both in the “head” (fast-moving items that are easier to forecast) and the “tail” (slow-moving or intermittent demand items).

The Benefits of Advanced Demand Forecasting

Adopting advanced demand forecasting solutions unlocks substantial operational and financial advantages:

- Higher Customer Satisfaction: Ensuring product availability improves customer experience and brand reputation. For example, Aston Martin faced growing demands from an international clientele and needed to improve first-time availability without increasing inventory. By leveraging AI-powered forecasting, they reduced safety stock by 18% while improving service levels to 97.1%.

- Better Resource Allocation: Placing inventory in the right locations optimizes fulfillment and sales.

- Supply Chain Cost Reduction: Companies using AI-powered demand forecasting see a 15-30% inventory reduction while improving product availability and inventory turns. Companies can also reduce overhead due to overtime and expedited freight by more than 50%.

- Lower Obsolescence: Improved demand accuracy reduces overstocking and discount-driven losses.

- Enhanced Productivity: Automation decreases planner workload by up to 90%, freeing resources for strategic tasks.

- Increased Sales Performance: Businesses leveraging probabilistic forecasting can achieve up to 99% product availability and when combined with multi-echelon inventory optimization, you can reduce lost sales by 20-50%.

- Reduction in Lost Sales: In the retail sector, there’s a 50% chance of losing a sale due to service failures, though this can vary by product and sector. Employing probabilistic forecasting enhances your forecast accuracy more effectively than single-number methods. By adopting this approach, you can boost forecast accuracy by 5% and reduce forecast errors by 10-20%.

Why Spreadsheets Fall Short in Demand Forecasting

While spreadsheets remain a staple in business operations, here’s why they lack the agility and accuracy required for modern demand forecasting:

- Limited Collaboration: Multiple versions lead to errors and misalignment across teams.

- Error-Prone: Manual data entry increases the risk of miscalculations.

- Inflexible Modeling: Spreadsheets provide static calculations rather than dynamic, scenario-based forecasting.

- Lack of Automation: Updating spreadsheets is time-consuming and inefficient compared to AI-driven systems.

Move Beyond Spreadsheets: Smarter Supply Chain Data Management

Traditional spreadsheets struggle to keep up with the complexities of intermittent demand—especially when managing a large SKU portfolio.

To forecast with confidence, you need to understand the full range of demand patterns, not just historical averages. Advanced demand forecasting and analytics empower businesses to build precise demand and inventory models, ensuring high service levels and optimized stock—without burdening planners with excessive manual work.

Industry-Specific Impact:

Retail:

- Reduced stockouts by up to 30%

- Improved seasonal planning accuracy

- Enhanced promotion effectiveness

- Better new product introduction success

Manufacturing:

- Optimized production scheduling

- Reduced changeover costs

- Improved supplier collaboration

- Enhanced capacity utilization

Healthcare:

- Better management of critical supplies

- Reduced expired product waste

- Improved service levels for essential items

- Enhanced emergency preparedness