Navigating the Supply Chain Wars: Strategies for Wholesale Distribution Success

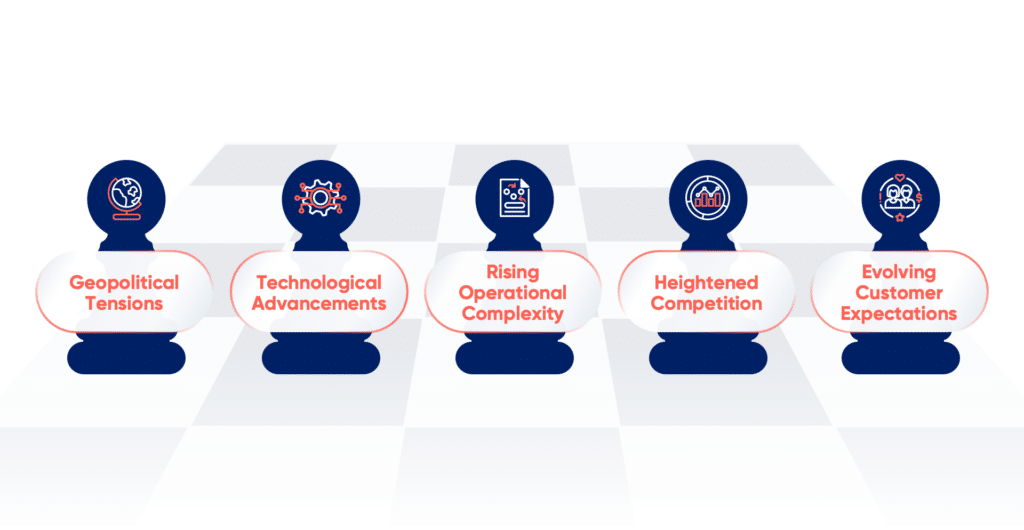

In today’s volatile global landscape, wholesale distributors and aftermarket companies face an uphill battle to maintain service levels, manage costs, and ensure competitiveness. ToolsGroup identifies five key drivers shaping the future of supply chains: changing customer expectations, heightened competition, rising operational complexity, technological advancements, and geopolitical tensions. Let’s explore these challenges and strategies to overcome them.

The Challenges of Modern Supply Chains

- Geopolitical Tensions

- Trade wars and regionalization are pushing businesses to adapt to localized supply chains.

- Conflicts in critical regions disrupt access to essential materials.

- Technological Advancements

- Real-time inventory tracking and predictive analytics give leading firms a competitive edge.

- Automation and machine learning are redefining operational standards.

- Operational Complexity

- Increased supplier diversification demands robust relationship management.

- Regional production hubs require tailored distribution networks.

- Heightened Competition

- Direct-to-customer (DTC) channels challenge traditional wholesaler roles.

- Consolidation and new entrants reshape the competitive landscape.

- Evolving Customer Expectations

- Faster delivery, customized solutions, and real-time communication are now essential.

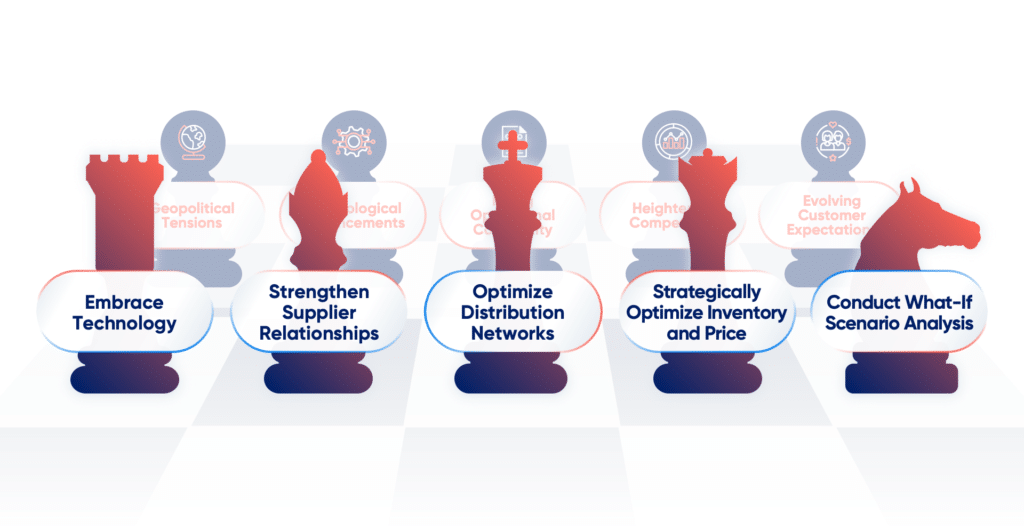

Winning the Supply Chain Wars

To thrive amidst these challenges, ToolsGroup recommends five strategic pillars:

1. Conduct What-If Scenario Analysis

Simulate potential disruptions to plan and respond proactively.

2. Optimize Inventory and Pricing

Use AI-driven insights for stock mix optimization and dynamic pricing, reducing excess stock while meeting service level goals.

3. Strengthen Supplier Relationships

Build diversified and collaborative networks to enhance visibility and reliability.

4. Optimize Distribution Networks

Adapt warehouse locations and logistics for localized supply chains.

5. Embrace Technology

Leverage digital platforms for predictive analytics, automation, and end-to-end inventory transparency.

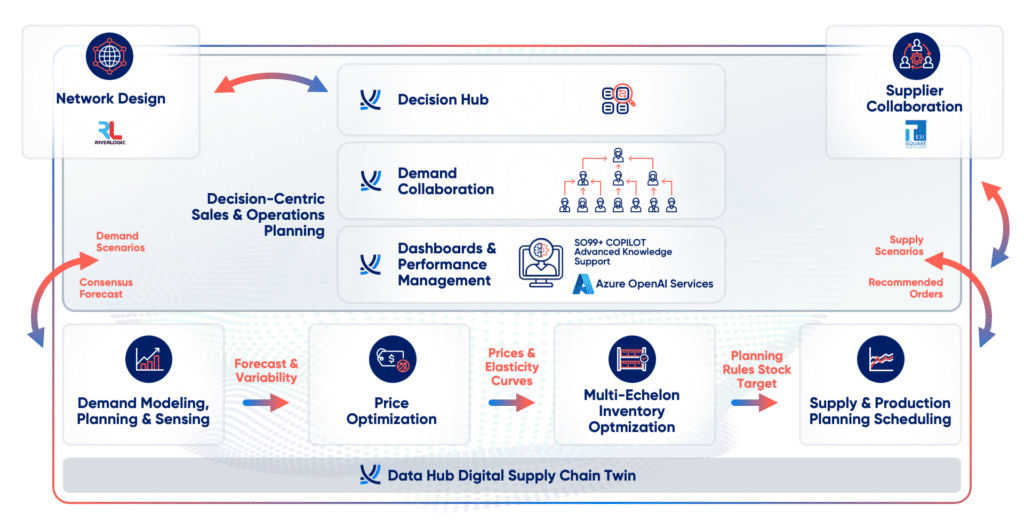

ToolsGroup – Your Secret Weapon in the Supply Chain Wars

ToolsGroup has a powerful portfolio of solutions designed to help you thrive in times of uncertainty and risk.

1. Conduct What-If Scenario Analysis

Decision Centric Planning: Prepare for unexpected events through scenario planning and improved rapid response decision making.

- Decision command center for fast event response

- Asynchronous collaboration and scenario analysis

- Demand collaboration

- S&OP

2 . Optimize Inventory and Pricing

AI Driven Inventory and Price Optimization: Set inventory strategies to match business segment priorities. Invest to buffer inventories of critical goods and use pricing to intelligently respond to tariffs.

- Optimize inventory based on service-level goals by product segment

- MEIO, stock-to-service curves, and stock mix optimization

- Dynamic price optimization, driven by market dynamics and material price changes, such as tariffs

- Automatic inventory replanning based on price elasticity

3. Strengthen Supplier Relationships

Supplier Collaboration Network: Diversify sources and build collaborative partnerships to secure reliable supply chain and improve visibility.

- Collaborate on POs and demand forecasts

- Real-time visibility into ASNs and shipping notices

- Real-time risk and issues detection with proactive alerting

- Supplier performance management

4. Optimize Distribution Networks

Network Design and Optimization: Reconfigure warehouse locations and logistics for regional or localized supply chains.

- Long-term what-if strategic analysis

- Visual, interactive network models

- Incorporation of all costs for financial impact analysis

5. Embrace Technology

AI Powered Digital Supply Chain Planning Platform: Digitalize and invest in predictive/prescriptive analytics, automation, and digital platforms to improve efficiency and end-to-end inventory transparency.

- End-to-end visibility

- Management by exception

- Frequency-based self-adaptive probabilistic forecasting, which is the easiest to use and best for both fast- and slow-moving items

- Machine Learning for seasonality, sales calendars, promotions, new product introductions, external causals

- Automated replenishment and proposal generation

- Dynamic multi-sourcing and transport management

- Modular, composable and extensible architecture for easy third-party app integration

- Forward buy what-if scenario analysis

Success Stories: ToolsGroup in Action

Many companies have transformed their operations with ToolsGroup’s solutions in an increasingly challenging market:

- Mitsubishi Electric: Achieved a 30% reduction in spare parts stock while boosting service levels 10 points to 97%, even during seasonal peaks.

- Aston Martin: Improved first-time availability (FTA) across all car categories with an 18% reduction in safety stock.

- Pilkington Automotive: Improved OTiF by 10% while consistently achieving a top-level forecast accuracy above 97%.

- Amara: Achieved a 12% MRO inventory reduction in 6 months, which improved working capital 38%.

- Borg Warner: Reduced inventory 10% while increasing service levels to from 91-92% to 98%.

These case studies underscore the importance of aligning technology with operational strategy to gain a competitive edge. According to Thomas Schuhmann, General Manager Business Development and Sales Direct Markets, Mitsubishi Electric Europe B.V., this makes all the difference when facing the unexpected. “Within three years, ToolsGroup helped us reduce our spare parts stock by 30 percent, and we increased our service level from 87 to 97 percent. Even during seasonal demand peaks we are now always able to achieve this exceptional service level.”

Within three years, ToolsGroup helped us reduce our spare parts stock by 30 percent, and we increased our service level from 87 to 97 percent. Even during seasonal demand peaks we are now always able to achieve this exceptional service level.

Whether the supply chain wars bring rising costs, limited materials availability or unexpected peaks and troughs in demand, ToolsGroup is prepared to help you navigate that uncertainty–and thrive.

Final Thoughts

As supply chain dynamics continue to evolve, wholesale distributors must remain agile and innovative. By embracing digital transformation and strategic planning, businesses can turn their supply chains into powerful tools for success. ToolsGroup’s AI-powered solutions are helping companies navigate uncertainty and stay ahead of the curve.

Click here if you would like to download our presentation on winning the supply chain wars or book a meeting with our experts. Let’s win the supply chain wars together!