The Best Way to Set Inventory Targets?

Gartner’s insights are quite good and it’s not often that I disagree, but on the topic of setting inventory targets I have to differ with the conclusions of a recent report, “Cover Considerations — How to Optimize Retail and Consumer Product Inventory Targets.”

There is a story about Abraham Lincoln arguing a case as a young lawyer. In his summation, he tells a story about a farm boy who runs to his father and says, “Pa, pa, the hired hand and sis are in the hay loft! She’s a liftin’ up her dress up and he’s a pullin’ down his pants and they are going to pee all over the hay.” The farmer puts his hand on the agitated boy’s shoulder and replies, “Son, you’ve got the facts right, but you’re drawing the wrong conclusion.”

In their report, Gartner has correctly identified the complexities of setting optimized inventory targets, but I would argue that they haven’t proposed the best way to solve it. That is, they have their facts right, but I’d say they have suggested the wrong conclusion.

Gartner’s report says that setting optimized inventory targets requires precisely incorporating interlocking variables like demand variability, service level targets, lead times, working capital and replenishment cycles. Then they outline six criteria for optimizing product flow through the supply chain to maximize order fulfillment and minimize inventory.

On the demand side, Gartner says inventory targets must consider demand forecast accuracy and demand volatility. They say that inaccurate forecasts require companies to hold excess stock to guard against shortages. They say that demand volatility (caused by natural fluctuations over time, sudden market shifts and extreme seasonality) necessitates extra inventory to account for these demand instabilities.

On the supply side, Gartner says those targets must consider both order supply and supply order reliability (orders arriving on time and in full), including:

- Lead time from order to receipt – Linking inventory held in DCs or stores to lead times

- Frequency of placing orders – Connecting order frequency to inventory needs

- Order Receipt Lead Times – affect the amount of inventory that must be held in the meantime

- Order Receipt Completeness – governs inventory needed to mitigate risk of short shipments

So far so good, although I would suggest that the list is somewhat incomplete. There are other considerations that impact inventory targets. Two important ones are demand order size and order frequency. For instance, demand streams of a fewer large incoming orders require more inventory than similarly sized demand streams of many smaller orders. The flow of small orders creates a natural probability-based consistency that the fewer larger orders do not provide. (Solo Cup talked about this phenomena in a previous blog). Measuring and accounting for these variables can greatly improve inventory targets.

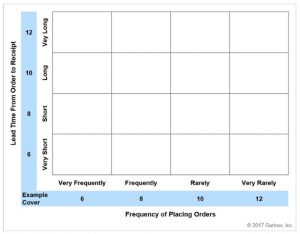

But where we really part ways is in the conclusion of how to deal with this complexity. The report suggests a manually-intensive process for trying to account for these considerations. They recommend creating grids with x/y axes to assess individual products against each set of criteria in order to estimate the inventory needed to cover orders.

For most companies this would entail building grids for hundreds or thousands of products, especially if viewed at the granular SKU-Location level analysis needed for good inventory optimization practices (see our previous blog: What’s wrong with ABC inventory classification?).To do an analysis of that magnitude using manually-intensive techniques could be a stultifying exercise.

But even more important, a grid building exercise is really just a shortcut that substitutes for a precise demand, inventory and supply model. An approach that lacks this precision will almost always fall far short of optimized targets, particularly in more challenging scenarios like intermittent demand, stringent service levels or multi-echelon networks.

This job really calls for an automated system that can precisely capture these elements in a single, coherent model. Inventory targets are best set with planning tools that employ adaptive probability-based algorithms built to deal with supply and demand volatility and dozen of other considerations.

I agree with Gartner’s analysis – setting inventory targets is a complex problem. But it’s a problem best solved by computer modeling and a highly automated approach to supply chain planning.