Right and Left Brain Thinking for Improving Supply Chain Planning ROI

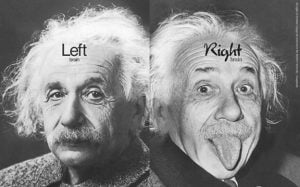

There are two kinds of thinking, left brained and right brained, and each processes information and makes decisions very differently. As shown in the image above, the left brain is the logical, ordered, rational and analytical hemisphere. It’s the ROI half. The bottom line half. So in business decision making, left brained thinking tends to have the “upper hand”. However, focusing exclusively on this linear type of thinking can hinder the evolution of an organization if it restricts the potential of technology.

Right brained thinkers aren’t top of mind when pulling together the team to explore an investment in technology. Who wants the guy on the right making the big business decisions?

Figure 1 Image Source: https://blog.enotes.com/2013/03/29/are-your-right-or-left-brained/

But omitting them from the process will leave out perspective that could drive your strategy for decades. Why? Right brained thinkers look at the whole picture, understand how it works, ask questions about why things work the way they do, determine if the rules really apply, and then create new potentials based on all the information. In short, they like to look at what already exists and make something new. Here are some of the strengths of a right brained thinker:

- Solving problems by looking at similarities and patterns

- Answering open-ended questions rather than choosing from predetermined answers

- Thinking about why they’re doing something or why rules exist (and how they could be broken)

- Processing multiple ideas simultaneously

- Assimilating whole chunks of information rather than break them down into discrete facts

- Naturally creative problem solving

That’s a powerful combination, but one that is often discounted in supply chain decision making. The resistance to this type of thinking is ironically in the numbers. According to a 2014 study by creative agency Sommer + Sommer, 41% of people are left brained, 27% are right brained, and 32% have equal influence on thinking. But the left brain dominance becomes much more heavily skewed when you consider that 57% of men are left brain-dominant, while 70-80% of supply chain employees are men and 95% of top level decision making positions are held by men (according to a 2015 Fronetics blog). That’s a lot of momentum focused on the analytical.

The opportunity here is to go beyond the supply chain planning ROI and “think outside the box”. For instance, let’s not just automate what we are doing already and run the numbers. Engage the power of the right hemisphere to transform your business. Think about the “could be” that is now possible with the adoption of technology. Allow daydreams about operational possibilities and consider them in your roadmap. This may require a culture shift in the organization to encourage your peers to embrace the potential of emerging technologies for what they are, and how they can improve your business. After all, remember that cell phones and laptops were once emerging technologies.

Some of our clients like Costa Coffee, Lennox and Cipla, did just that. They saw an opportunity based on market trajectory and took an approach to use the power of predictive analytics to re-engineer their processes. Ultimately by engaging the creative, visionary part of their thinking process they created a new business model that elevated their performance, efficiency and margins.

In our recent Supply Chain Planning Brief, Investing to Improve Your Business: Calculating Your ROI and TCO, we try to help readers consider both sides of the problem. We go into significant detail about the equations to use when creating a business case to support an investment in supply chain planning software. These include improved service levels, inventory savings, and limiting disruptions while improving productivity. But it also includes some right braining thinking on how to make your business more agile, more responsive, more flexible by incorporating the creativity, imagination, analytics, and mathematics to create a supply chain of the future.