Dynamic Inventory Replenishment Optimization Guide

Disruptions in the supply chain happen with surprising regularity. Financial crises, global tensions, supply shortages, technological innovations, and regulatory changes are inevitable– we just can’t predict when they’ll strike. This uncertainty makes dynamic inventory replenishment optimization essential for business success. Effective inventory optimization directly impacts customer satisfaction, loyalty, operational costs, and waste reduction – making it a critical business function in today’s volatile market.

Why Traditional Stock Management Fails During Disruptions

When unexpected disruptions occur, conventional inventory systems fail to adapt quickly enough, resulting in costly delays, critical shortages, excessive overstock, and damaged customer relationships. Stockouts and overstocks carry serious consequences: the global retail industry loses an estimated $1.75 trillion annually due stockouts, while overstocks tie up capital, inflate storage expenses, and force profit-killing markdowns.

Every day spent with suboptimal inventory optimization means lost revenue and opportunity. Modern businesses must approach stock optimization as a dynamic, responsive system rather than a static holding pattern.

High-Performance Inventory Through Dynamic Inventory Replenishment Optimization

High-performance inventory ensures products are available precisely when needed through intelligent management systems. An effective supply chain inventory optimization strategy balances optimal stock levels with minimal costs while ensuring product availability and safeguarding exceptional customer experiences.

This advanced approach takes advantage of probabilistic planning that acknowledges market volatility and employs probability distributions to account for variability in demand and lead times by:

- Maximizing availability while boosting operational efficiency

- Implementing data-driven inventory optimization techniques

- Eliminating both visible and hidden inventory costs

- Strengthening customer loyalty through reliable product availability

- Continuously monitoring key performance metrics for stock optimization

The Dual-Component Framework for Dynamic Inventory Replenishment Optimization

Modern inventory optimization consists of two critical components. First, a sophisticated analysis and decision-making process, that incorporates real-time data and requirements. Second, the strategic activation of intelligent stock optimization based on probabilistic modeling outcomes.

Component 1: AI-Powered Probabilistic Forecasting for Inventory Optimization

Effective forecasting enables businesses to navigate uncertainty and respond rapidly to disruptions. AI-enhanced probabilistic forecasting represents a revolutionary approach to supply chain inventory optimization that transcends traditional forecasting methods, providing a multidimensional predictive framework.

This advanced dynamic inventory replenishment optimization technique delivers:

- Real-time data integration: Analyzes comprehensive internal and external demand factors across all locations, while monitoring current inventory positions and potential disruptions.

- Multi-scenario prediction: Generates diverse forecast possibilities with precise probability assessments for informed decision-making.

- Risk visualization: Enables teams to identify potential inventory vulnerabilities and opportunities, with transparent reasoning behind stock optimization recommendations.

- Superior predictive accuracy: Offers significantly more adaptable and precise forecasting compared to conventional methodologies.

New to probabilistic forecasting?

Check out our library of videos, case studies, and other helpful resources here →

Component 2: Multi-Echelon Approach to Dynamic Inventory Replenishment Optimization

Multi-Echelon Inventory Optimization (MEIO) identifies the most efficient and cost-effective points throughout the supply chain against variable demand levels. By utilizing probabilistic forecasting insights, organizations can strategically position inventory across their entire network. This data-driven approach enables precise inventory optimization of placement and quantities.

MEIO delivers exceptional stock optimization through:

- Precision targeting: Uses granular forecast intelligence to establish optimal inventory positions across all supply chain locations.

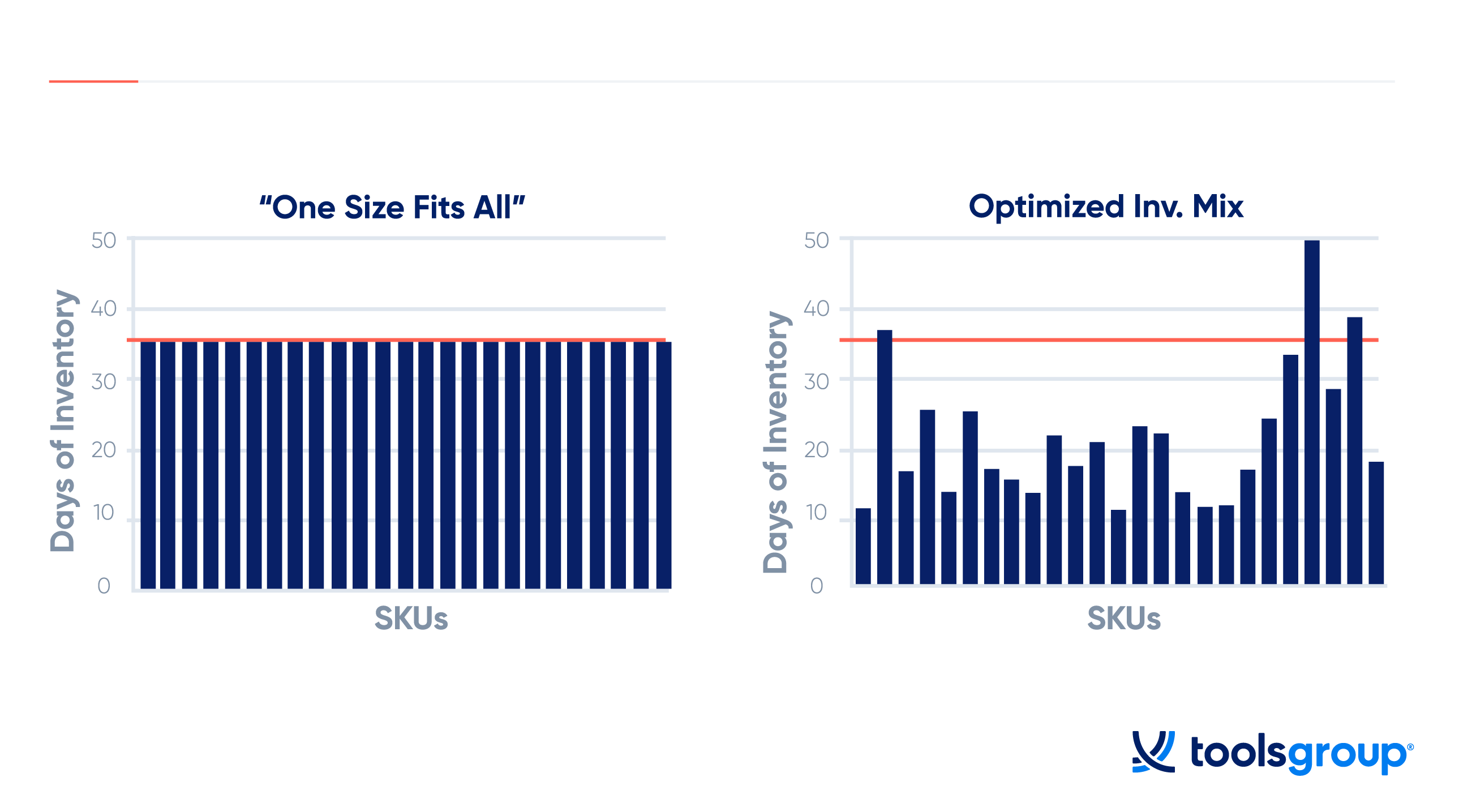

- Goal-aligned optimization: Calibrates inventory against specific business goals and service level targets through dynamic inventory replenishment optimization

- Smart resource allocation: Eliminates excess inventory while maintaining robust demand fulfillment capabilities.

- End-to-end integration: Evaluates multiple demand scenarios to position inventory in the most cost-effective manner possible.

Transform Inventory into a Competitive Advantage with Dynamic Inventory Replenishment Optimization

Technological advancement, enhanced global visibility and rapid market responsiveness have transformed inventory management into a real-time, strategic imperative. Static inventory approaches are becoming obsolete, replaced by intelligent supply chain inventory optimization systems that can adapt to market complexities.

By implementing high-performance inventory through dynamic inventory replenishment optimization, organizations can turn disruptions challenges into competitive advantages. This strategic approach enables intelligent responses to uncertainty, leading to improved resilience, significant cost reductions, and the agility to quickly adapt to unexpected market development.