Reduced Latency – Gartner on “Sense and Respond” Supply Chain Planning

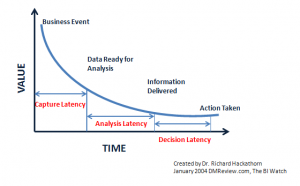

Gartner says supply chain planning needs to move to more of a “sense and respond” model—reducing the latency between sensing demand and execution response. The research and advisory firm says that supply chains need to profitably respond to demand changes by executing in a near real-time manner. This reduces the length of the latency curve (shown above) and therefore increases the value of the response.

Gartner believes the changing nature of supply chains—due to increasing globalization, unpredictability, volatility, risk, and complexity—will drive companies to invest more in what they call “response planning”. They say technologies such as cloud, in-memory computing, complex-event processing, and prescriptive analytics are helping to make response planning possible.

A recent report entitled “Supply Chain Planning — Coping With Uncertainty in Global Networks”, Gartner focuses on the consumer products supply chain as a proxy for the changing nature of supply chain management. Gartner sees a strategic opportunity to leverage downstream data, and predicts that, “90% of demand-driven value network [DDVN] leaders in consumer products will leverage downstream consumption as pull signals to drive near-term upstream supply execution.”

This new approach is needed, they say, to overcome shortcomings in demand forecasting, particularly at the daily/weekly and location granularity. Gartner’s recent benchmarking survey of key consumer products metrics shows the industry average SKU-level forecast error for one month out (lag 1) to be 22%. For new products, that error rises to 48%.

Gartner says consumer products firms that align upstream production and materials replenishment with downstream pull signals—POS, retail store/warehouse inventory, retail warehouse movements— reduce forecast error, decrease inventory, have more predictable supply operations, and deliver equal or higher service.

“They set inventory buffers based on product level, average daily demand, range of demand variation and supply reliability,” Gartner explains. “These buffers are reviewed regularly to reflect recent patterns. With these product-specific buffers, data on downstream consumption and more responsive upstream supply, they can better align inventory and supply execution to replenish what is needed and when, without excess inventory or waste.”

This approach necessitates tight integration between planning and execution. “Sense and respond” supply chain planning not only requires improvements to advanced planning capabilities—it requires the convergence of planning and execution systems. This is the “Predictive Commerce” model we discussed in the last two blog posts.

Predictive Commerce, as you may recall, connects upstream demand sensing with downstream supply chain planning and execution. The foundation of any Predictive Commerce application is a single, integrated, predictive forecasting and dynamic replenishment model. This model takes advantage of new ways to capture the demand signal and its impact on the supply chain. It is the antidote to demand volatility and expanding product portfolios.

“Improvements related to inventory, cost and service are the primary impact areas that result from aligning supply execution with actual downstream consumption,” says Gartner. “Supply chain leaders should start here with their analysis to build the business case for aligning with downstream pull signals,” enabling sense and respond supply chain planning.