Thriving in Uncertainty: The Antifragile Supply Chain

Over 2,000 years ago, Greek philosopher Heraclitus said that “change is the only constant in life.” Today, this phrase serves as a mantra of self-help gurus, financial planners and business executives, yet many of the tools most individuals and businesses use and the plans they put in place try to take uncertainty out of the equation. History has taught us that it’s an impossible task.

In the last few years alone, we’ve had a global pandemic that put the world on pause, natural disasters and accidents that have disrupted infrastructure, as well as territorial and political conflicts that have added more layers of insecurity and disruptions. In the face of these local, regional and global challenges, the concept of an antifragile supply chain has never been more relevant.

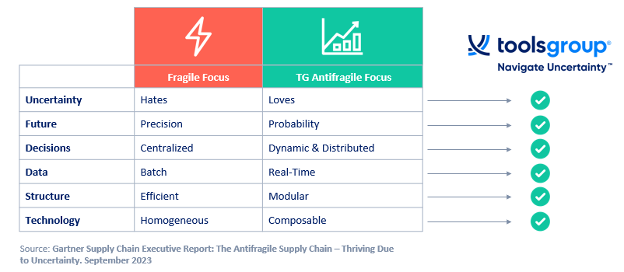

Gartner’s Tim Payne wrote a fascinating article and report about antifragile supply chains and how organizations can learn to cope with uncertainties. In his article, Payne revealed that while almost 90% of Chief Supply Chain Officers believe that change is here to stay, “fewer than 10% of companies today can produce a gain in value due to exposure to uncertainty.” This is a startling statistic that highlights the fact that conventional supply chain planning software is not able to support today’s world of adverse events and uncertainty.

Let’s examine what having an antifragile supply chain really means and take a look at a global organization that was able to react quickly when Covid hit.

What is an antifragile supply chain?

In a world where disruptions are inevitable, the antifragile supply chain stands out as a beacon of resilience and adaptability. The antifragile concept was introduced by Nassim Nicholas Taleb in his book, “Antifragile: Things That Gain from Disorderi.” The term describes systems that not only withstand shocks but actually thrive in the face of uncertainty. This is a paradigm shift from traditional supply chain management, which often focuses on minimizing risks and maximizing efficiency. Instead, an antifragile approach acknowledges the inevitability of disruptions and leverages them as opportunities for growth and improvement.

One key principle of an antifragile supply chain is decentralization. Rather than relying on a single point of failure, such as a centralized warehouse or distribution center, an antifragile system disperses resources across multiple nodes. This redundancy not only reduces the impact of disruptions but also fosters agility and flexibility. Take, for example, the case of Dr. Schär, a global leader manufacturer of gluten-free foods.

Dr. Schär – Leading by Example

Headquartered in Italy, Dr. Schär leads the market in gluten-free foods, offering a wide range of products for special dietary needs. With over 1,750 employees globally, the company operates 18 sites in 12 countries, boasting 12 production plants and 26 distribution warehouses, delivering to over 100 countries worldwide. During the Covid Crisis, Dr. Schär faced considerable demand and supply variability.

In a recent webinar hosted by Supply Chain Now, the supply chain leaders at Dr. Schär spoke about how they were able to thrive in the midst of this uncertainty thanks in part to their just-completed digital supply chain transformation. With all the supply chain planning activities digitized, and with the help of the advanced machine learning and probabilistic capabilities within ToolsGroup’s SO99+ platform, the team was able successfully plan sales forecasts, fulfillment and replenishment for every SKU at every location, along with rough and finite capacity planning.

With the redesign of the Supply Chain Planning process, Dr. Schär was able to increase order fill rates by 1.5%, improve forecast accuracy by 3%, and enhance freshness upon shipment by 1.8%. Despite a larger product mix, heightened variability and increased volumes, Dr. Schär has managed to optimize their inventory performance.

Embracing uncertainty

An antifragile supply chain embraces experimentation and learning. Instead of rigidly adhering to predefined processes, organizations continuously test new strategies and technologies, learning from both successes and failures. This culture of innovation enables companies to rapidly adapt to changing market conditions and emerging threats.

Another crucial aspect of the antifragile supply chain is dynamic risk management. Traditional risk management approaches often focus on predicting and preventing specific risks. However, in a complex and uncertain world, this approach falls short. Antifragile organizations embrace uncertainty and view risk as an inherent part of business operations. Rather than attempting to eliminate risk, they build resilience by diversifying their risk exposure and developing robust contingency plans.

Learn more about building an antifragile supply chain

The concept of the antifragile supply chain offers a compelling framework for thriving in uncertainty. By embracing decentralization, experimentation and dynamic risk management, organizations can build resilience and agility in the face of disruption. In a world where change is the only constant, it’s not enough to merely survive—businesses must learn to thrive amidst uncertainty. As we navigate the challenges of the 21st century, the antifragile supply chain provides a roadmap for resilience, adaptability and sustained success.

[1] Nassim Nicholas Taleb, Antifragile: Things That Gain From Disorder, Random House, 2012