Should I Outsource Supply Chain Planning?

Should you manage your own planning processes or outsource supply chain planning? We will describe how to choose a planning partner, but first let’s take a look at why to consider outsourcing at all.

In an economy where only the fittest survive, shedding non-core business processes is one of the most time-tested ways to cut costs while improving performance. In the initial years, companies focused on outsourcing functions like finance, customer service and HR. By outsourcing their support functions, they were able to increase flexibility while reducing operating costs.

Now companies have started outsourcing business processes like supply chain planning, direct procurement, order management, inventory optimisation and reverse logistics. So supply chain outsourcing has evolved from a method to create flexibility and cut costs to one of forming strategic business partnerships. These business partners allow companies to focus on core business processes and free up internal resources, whilst gaining access to world class capabilities.

Dealing with supply chain planning issues can be deadly. Market and consumer behaviour is more unpredictable than the weather. Customers demand what they want, when they want it and how they want it. How you deliver to their demands is your problem. This leads to immense pressure on your supply chain. No one is immune. Times are tough, competition is fierce and price is king.

Outsourcing supply chain planning allows companies to be more efficient and effective. Suddenly employees aren’t expected to complete activities that they aren’t proficient in, since outsourcing provides access to high calibre professionals specialising in that specific activity. These are people that know all the traps and know how to navigate around them. So for instance, much less obsolete stock, because the outsourced demand planner doesn’t order stock based on gut feel. Meanwhile internal resources are made available to focus improvement efforts on the core business processes.

Is this for your company? As with many important questions, there is no one right answer, nor simple criteria to determine whether outsourcing will be beneficial to your company. Each company, business process and potential business partner must be scrutinised on its own merits, to ensure the effort versus reward is proportional.

We have seen, however, big returns from companies adopting a supply chain planning BPO model, such as optimized working capital, reduced transport cost by 20+%, and reduced cancelled orders by 30%. In one example, a global consumer goods manufacturer delivered annual cost savings ranging from $325,000 – $500,000 per production site, preventive maintenance completion rates improved from 60% to 100%, and yearly production exception/error rates reduced from 12% to near 0%.

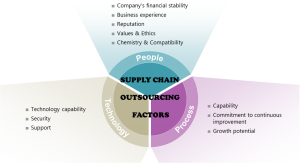

It is important to select a business partner that understands your business and lives your values. Do your homework on the company, read some of their case studies, and contact existing customers. You need a business partner that you can trust, that you know has your best interest at heart. The chart at the top of the page shows factors to be considered when selecting an outsourced supply chain planning business partner. We’ll comment on just a few:

People – Your supply chain outsourcing partner will be an extension of your company, therefore it is important that they are culturally compatible with your company and share the same values and ethics. They will be representing your brand to some degree, be it with suppliers, customers or internal stakeholders. It is of utmost importance that they have the skills and experience required and do not impair your brand.

Process – Whatever processes you outsource, you must be assured that your outsourcing partner has the capability to do the required tasks. Not only must your partner be committed to perform the tasks, but they must be committed to continuous improvement for you to benefit the most.

Technology – Technology plays a very important role in keeping the communication between you and your outsourcing partner alive. Technology infrastructure must be considered in terms of connectivity, availability, quality and security, including back-up infrastructure and business continuity solutions.

Eric Kingwill is managing director at FinStock with extensive across the board supply chain experience. Eric can be contacted at info@finstock.co.za.

Yolandé du Toit is an industrial engineer at FinStock focusing on supply chain strategy. Yolandé can be contacted at info@finstock.co.za.