Are You Prepared For The Next Chip Shortage?

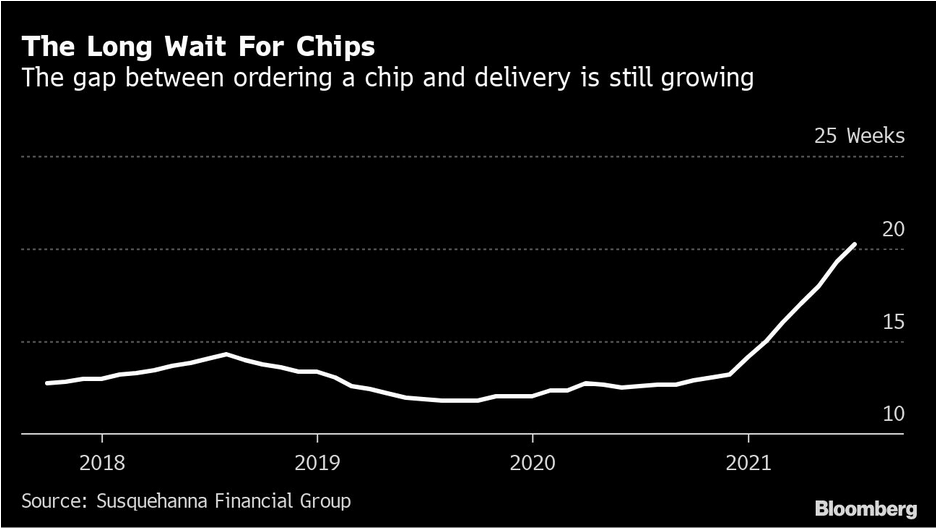

The worldwide chip shortage is bad and getting worse. Yet another aftershock of the COVID-19 pandemic, computer and hardware chips have been slow to recover amidst uncertain market conditions and a worldwide supply chain that was completely unprepared to deal with the impact. Severe supplier delays and material shortages have been felt on both the consumer and industry level – just ask any teenager still trying to get their hands on a PlayStation 5.

Nevertheless, the current chip shortage and other examples of supplier and material volatility were arguably avoidable. Most supply chains just aren’t built to deal with uncertainty, whether from a once-in-a-generation global catastrophe or a run-of-the-mill material shortfall. This goes back to how many organizations utilize traditional, demand-driven forecasting, which is heavily focused on forecast accuracy regardless of the fact that your demand forecast is always wrong. These forecasts are directly responsible for how organizations plan out how much they produce and guide the very core of their supply chain planning. So if they are ineffective–or, worse, inaccurate and unable to adjust to uncertainty within the market–the entire traditional “process” breaks down.

So the question is simple: If managing uncertainty is the key to effectively avoiding the next supply chain collapse, what can we do to properly address it and ensure we’re prepared for next time?

Production planning can alleviate supplier uncertainty like the chip shortage

Supply chain planning (SCP) is made up of a mix of interlinked technologies, starting with forecasting and moving through inventory optimization and replenishment. But if you want your supply chain to better adapt to uncertain supply, you need to have production planning software included alongside them.

So first off: What is production planning? It is a solution that, in a nutshell, helps you decide how much of a product to produce and ship across your supply chain according to a number of different factors, including cost, time-to-production, demand, market and/or supplier restraints, and much more. The end result is that you have an informed, effective production plan that adjusts to a myriad of market changes and allows you to make strategic choices that resonate across your entire supply chain.

In layman’s terms? With production planning technology, you have more control–over your supply chain, over uncertainty, and over your reactions to changes in the market.

How does production planning fit into the supply chain planning process?

So what does that mean regarding a sudden chip shortage? Well, as with any supply chain planning process, you start with a forecast. Remember how we mentioned that “traditional” ones tend to break down in scenarios such as this? In order to be truly effective, you need to design your forecasts to be able to quickly adjust to changes in the market. ToolsGroup has talked extensively about how probabilistic forecasting can be effective here.

So let’s say you have this highly reliable forecast. Great! You’ll use that to identify desired stock levels, which then funnels down to, well, producing for said levels. This is where the rubber meets the road, and production planning is the key to ensure this supply plan is always executable. Production planning is unique in that, while there are alternatives available, none really offer the same breadth or scope. The low-cost alternatives – such as spreadsheets – can end up causing more harm than good, and actually leave your supply chain in a worse state than it started. The sheer number of issues to manage that go beyond your control, from plant management to procurement to scheduling, seasonality, and demand peaks, mean that you need a multi-faceted solution that can account for every possible factor.

The benefits can be pretty staggering:

- Optimized inventory levels

- Higher customer satisfaction/service levels

- Lower WIP and semi-finished items, as well as overall set-up time impacts

The truth is that another chip shortage isn’t just possible – it’s inevitable. From housing materials such as lumber to food and dairy shortfalls, there are signs that an even more devastating event could be on the horizon. Companies that plan ahead – and have the technologies in place to ensure they are prepared – are the ones that are most likely to thrive when it does happen.

Here’s where to start to combat the chip shortage–and whatever tomorrow brings.

Remember that production planning is just one piece of a much larger conversation around optimizing your supply chain planning using digital technology solutions. In the last three years, we have seen excellent results by introducing production planning and scheduling solutions to different types of companies across numerous industrial sectors. Adopting technology developed to respond exactly to the types of production and supply chain management needs your organization faces is essential to ensuring that you are prepared for whatever comes next.

After all, it’s never too early to plan for the next chip crisis. But you can definitely be too late.

Angelo La Malfa is marketing communications manager for Plannet, which provides advanced planning, finite capacity scheduling and manufacturing execution software for manufacturers.